We focus on the research and development as well as the manufacturing of candy machinery and equipment. Our products encompass a variety of candy production lines and molding equipment, including 3D gummy lines, Alpine hard candy lines, lollipop pouring machines, and cotton candy production lines. Additionally, we offer auxiliary equipment such as sugar cookers, coating machines, and packaging machines, to meet our clients’ full process requirements from raw materials to finished product packaging. Whether you are a startup factory or a large candy enterprise, we can provide you with efficient, stable, and customized production solutions.

With only one device, you can easily make soft candy, hard candy, toffee, chocolate candy, and lollipop, and the shape and taste can be customized freely-this is our innovative table top gummy depositor! The desktop candy depositor is specially designed for laboratory, small batch production, factory proofing, and personalized customization, which not only has high precision, high efficiency, and high automation, but also is simple to operate. It is controlled by a full servo motor, with a multi-language PLC touch screen and a humanized interface, which can be easily used by users all over the world.

[/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column][/su_row]

[/su_column][/su_row]

| Model | GD-DA (Pouring type) | GD-DB (Plunger type) | GD-DC (Oil heating) | GD-V (Pouring type) |

| Deposit Times | 30-60times/min | 30 times/min | 30-60times/min | 20-35times/min |

| Productivity | 60-100 kg/h | Pouring volume: 0.5-30g (±0.3) | 60-100 kg/h | 40-150 kg/h |

| Voltage | 220V/50Hz | 220V/50Hz | 220V/50Hz | 220V/50Hz |

| Power | 4.2kw | 4.2kw | 4.2kw | 1.2kw |

| Nozzle/Piston | 10pcs | 10pcs | 10pcs | 20pcs |

| Machine Size | 1000*760*870mm | 800*1100*900mm | 1000*760*870mm | 804*660*1300mm |

| Weight | 100kg | 90kg | 100kg | 320kg |

The Market Targeted by the Table Top Gummy Depositor

[su_tabs] [su_tab title="Candy Manufacturing Plant" disabled="no" anchor="" url="" target="blank" class=""]The equipment can be used for new product proofing, small batch trial production, or customized order production, accurately control the formula and process, improve research and development efficiency, and quickly respond to market demand.[/su_tab] [su_tab title="Candy Brands & Retail Stores" disabled="no" anchor="" url="" target="blank" class=""]Suitable for on-site production and display, support personalized molds, create differentiated products, improve customer interaction experience, and help brand building and marketing.[/su_tab] [su_tab title="Food R&D Labs" disabled="no" anchor="" url="" target="blank" class=""]Used in formula development and functional sugar experiment, it is convenient to adjust the proportion of raw materials, test different pouring conditions, and realize a high-precision and stable test environment.[/su_tab] [su_tab title="Training Institutions" disabled="no" anchor="" url="" target="blank" class=""]As a teaching demonstration, it shows the technological process of candy production and helps students master modern candy production technology.[/su_tab] [/su_tabs] [su_row][su_column size="1/3"] [/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column][/su_row]

[/su_column][/su_row]

Technical Highlights of Small Scale Candy Depositor

[su_accordion] [su_spoiler title="Precision Pouring" open="yes" style="fancy"] The minimum pouring amount can be 0.2g, equipped with a suction function, preventing dripping, and the pouring amount and speed can be accurately adjusted.[/su_spoiler] [su_spoiler title="Mold Customization" style="fancy"] Support the customization of molds with various candy shapes and sizes to meet the needs of personalized product development. [/su_spoiler] [su_spoiler title="Automatic Cleaning" style="fancy"] Built-in cleaning program, one-button start, easy to solve the problem of sticky sugar residue, and save cleaning time. [/su_spoiler] [su_spoiler title="High-Temperature Heating" style="fancy"] The hopper is designed with electric heating and an oil interlayer, and the maximum heating reaches 150℃ to ensure the continuous flow of sugar.[/su_spoiler] [su_spoiler title="Intelligent Control" style="fancy"] Equipped with a Siemens PLC touch screen in Germany, which supports both Chinese and English, is easy to operate, and supports formula storage.[/su_spoiler] [su_spoiler title="Efficient Transmission" style="fancy"] The servo-controlled conveyor belt has a single/double mode, which is flexible and efficient and improves the efficiency of small batch production. [/su_spoiler] [/su_accordion] [su_image_carousel source="media: 575,576,577,578,579" controls_style="light" columns="2" align="center"]Full Support from Trial Production to Mass Production

Whether you are a newcomer to the candy industry or an enterprise user looking for a high-end candy prototype, this table top gummy depositor is an ideal choice. If you want to know more about the lollipop forming machine, the candy cooling tunnel, and other supporting equipment, please contact us to help you build a complete candy production line.[su_service title="Contact Gondor Machinery" icon="icon: edit" icon_color="#0aa5a5" size="20"][/su_service]

[wpforms id="527" description="true"]

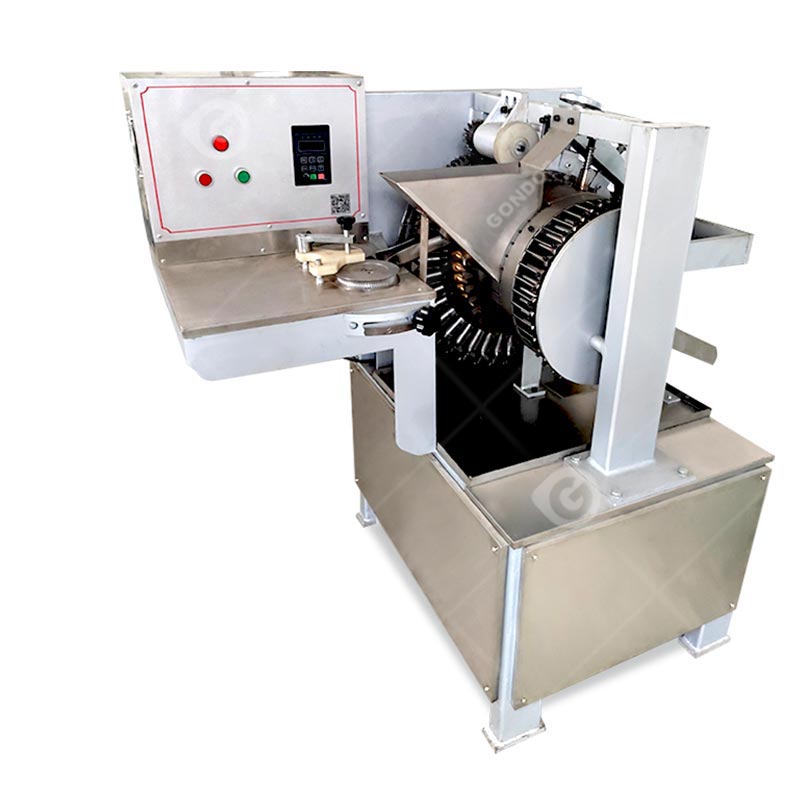

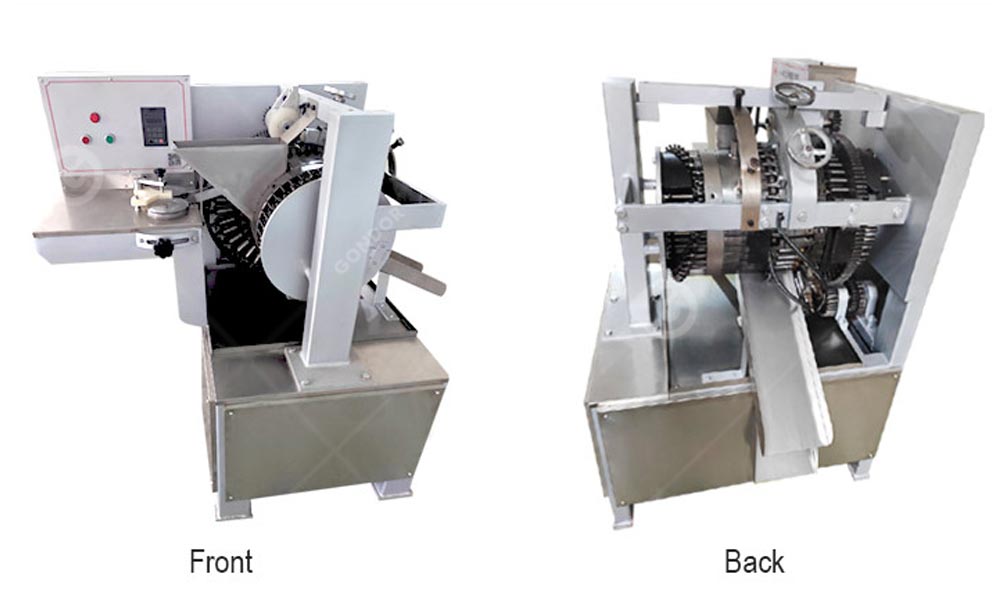

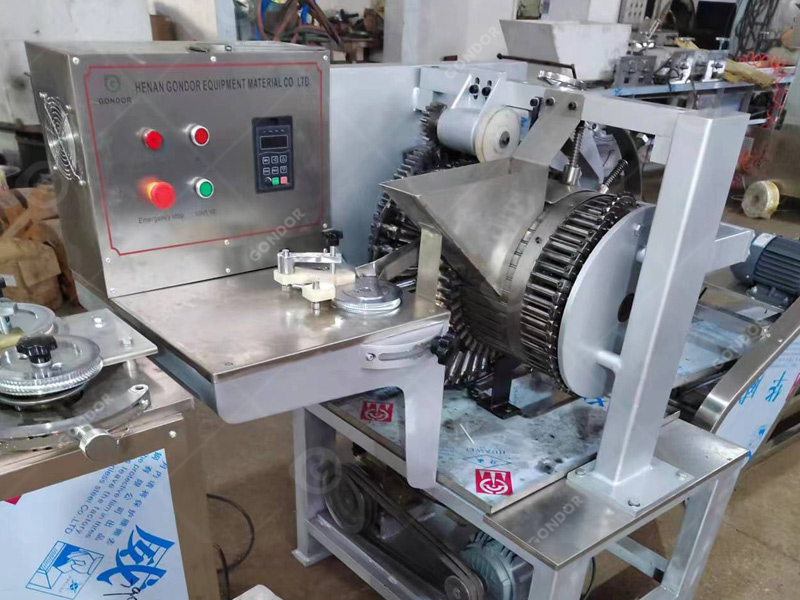

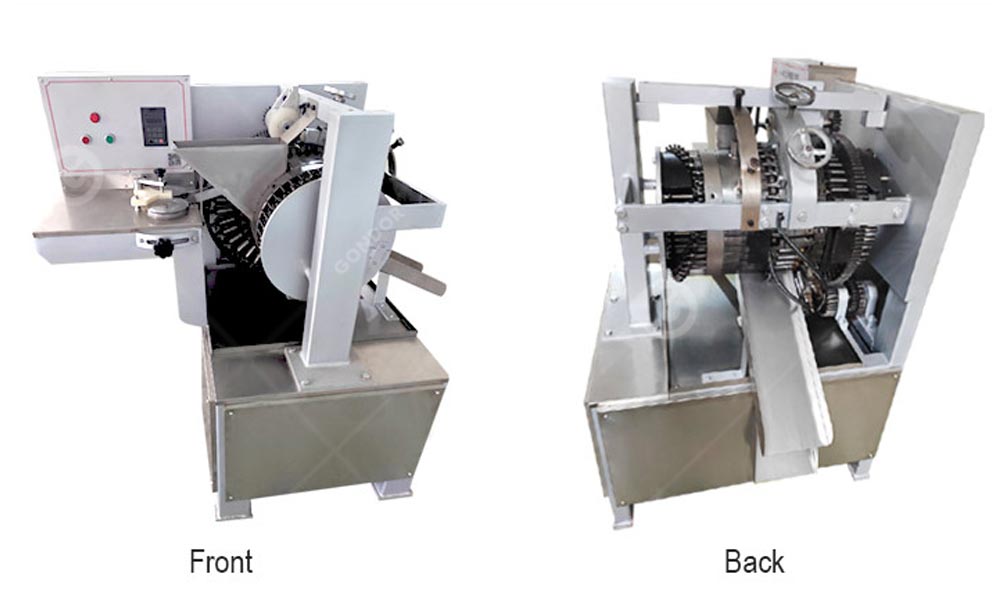

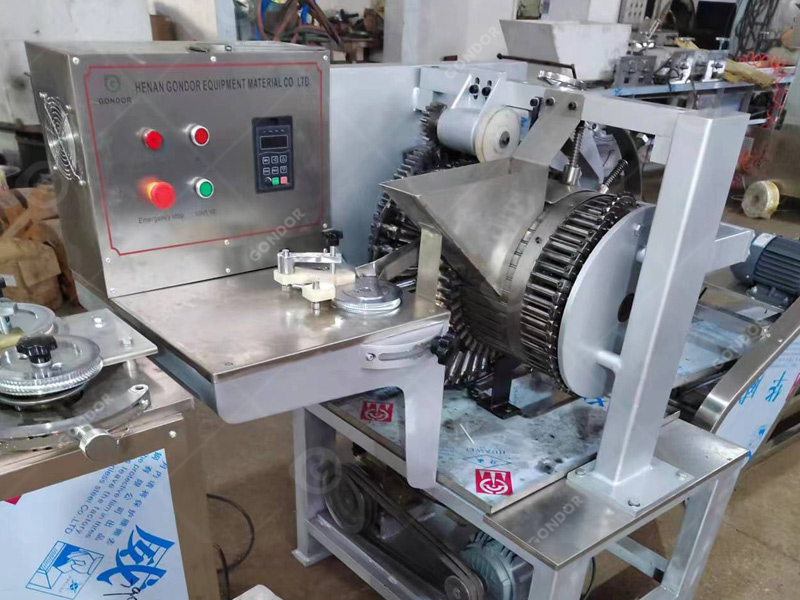

In the highly competitive candy industry, efficiency, accuracy, and quality are the magic weapons to win. Lollipop forming machine is an innovative equipment born for this purpose, aiming at completely innovate your lollipop production process. Whether it is a traditional spherical lollipop or a novel and unique whistle stick, this equipment can be easily controlled, bringing you higher productivity, lower cost, and more stable product quality.

[/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column][/su_row]

[/su_column][/su_row]

[/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column][/su_row]

[/su_column][/su_row]

| Modle | Outer size | Voltage | Powder | Candy size | Ball weight | Capacity | Machine weight |

| GD-400 | 100*900*1200mm | 220v/380v | 1.5kw | 18-35mm | 6-18g | 100-300kg/h 600-800pcs/min | 600kg |

The Broad Application Market of Lollipop Forming Machine

The ball lollipop forming machine is suitable for candy manufacturing enterprises of different sizes, including: [su_tabs] [su_tab title="Food Processing Plants" disabled="no" anchor="" url="" target="blank" class=""]In food processing plants, lollipop molding machine can realize large-scale and continuous production, meet the demand of a large number of orders, ensure the consistency of product size and quality, help enterprises respond to the market quickly and improve the overall production efficiency.[/su_tab] [su_tab title="Candy Manufacturers" disabled="no" anchor="" url="" target="blank" class=""]For candy manufacturing enterprises, the lollipop forming machine is the key equipment to enhance product diversity and competitiveness. It not only supports the production of lollipops with different tastes and specifications, but also reduces labor costs and achieves higher profit margins.[/su_tab] [su_tab title="Startups & Entrepreneurs" disabled="no" anchor="" url="" target="blank" class=""]For individual entrepreneurs, a compact and user-friendly lollipop molding machine is ideal for entering the candy market. With low investment and quick learning, even small batches can produce high-quality products, boosting startup success.[/su_tab] [/su_tabs] Whether you are in mass production or small batch customization, this equipment can accurately meet your dual requirements of output and quality. [su_row][su_column size="1/3"] [/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column][/su_row]

[/su_column][/su_row]

Extraordinary Performance Advantages of Ball Lollipop Forming Machine

[su_accordion] [su_spoiler title="High Precision & Consistency" open="yes" style="fancy"]- Advanced mechanical design and an intelligent control system are adopted to ensure that the shape, weight, and size of each lollipop are highly consistent.

- The sugar wheel can be flexibly adjusted, and the size of the sugar balls can be easily changed to meet diverse market demands.

[/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column][/su_row]

[/su_column][/su_row]

More Intelligent Candy Equipment Will Help You Upgrade the Whole Line

In addition to a lollipop forming machine, we also provide a range of high-end candy production equipment, including a candy depositor machine, a chocolate coating machine, and packaging machines, to help you create an integrated solution from production to packaging. If you need more candy production equipment, please contact our professional team, and we will provide you with tailor-made and efficient production solutions![su_service title="Contact Gondor Machinery" icon="icon: edit" icon_color="#0aa5a5" size="20"][/su_service]

[wpforms id="527" description="true"]

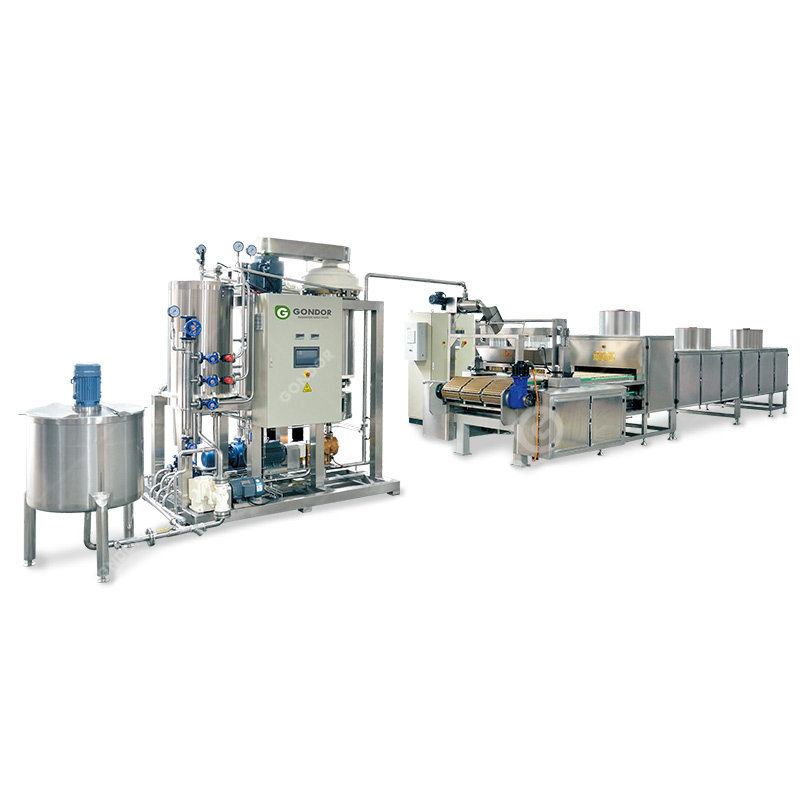

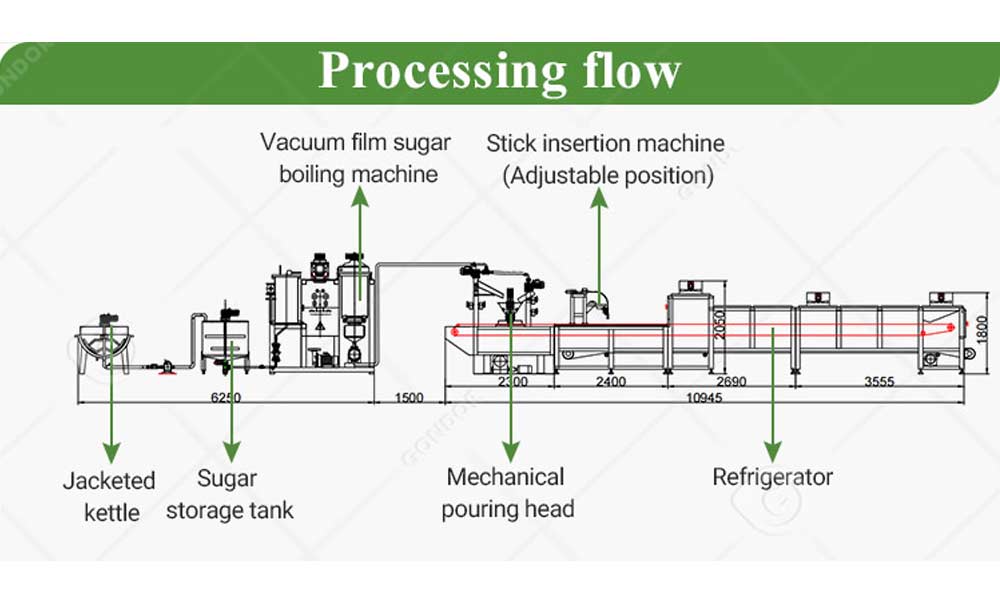

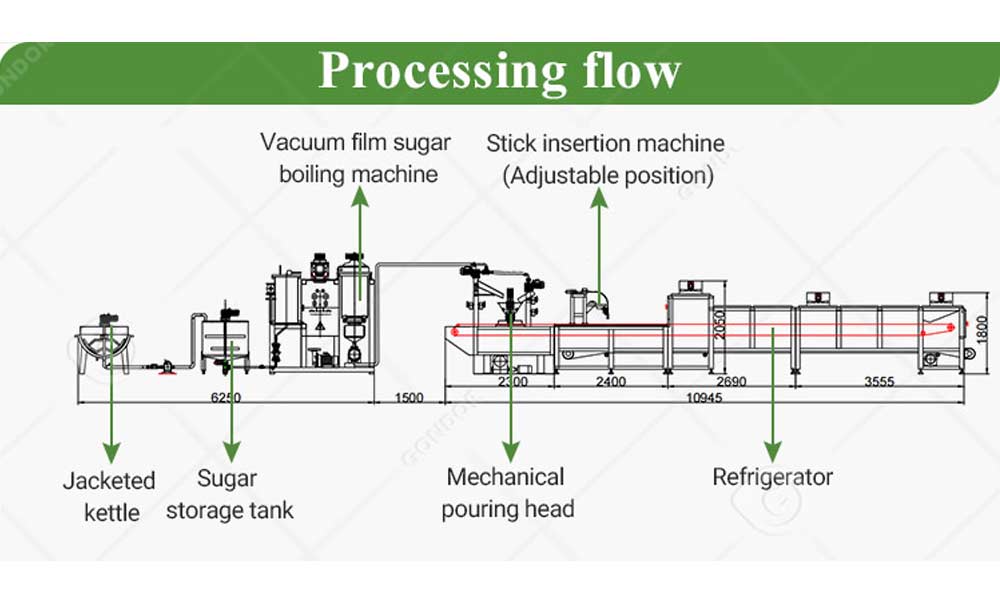

With the increasing demand for product diversification, quality stability and automation efficiency in the global candy market, the hard candy depositing line independently developed by our company came into being. Combined with many years' experience in food machinery manufacturing, the production line adopts international advanced automation technology, which is specially designed for producing high-quality hard candy with multi-color and multi-morphology. Moreover, the whole line is composed of core equipment such as sugar boiling pot, syrup storage tank, vacuum film sugar boiling machine, hard candy pouring machine and air-cooled tunnel. It is compact in structure and easy to operate. It is made of food-grade stainless steel and meets international standards such as GMP/HACCP/QS. In addition, by changing the mold flexibly, single color, two color, three color sugar, crystal sugar, button sugar and spherical lollipop can be produced efficiently, which fully meets the diversified market demand.

[/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column][/su_row]

[/su_column][/su_row]

[/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column][/su_row]

[/su_column][/su_row]

| Model | GD150B-S | GD300B-S | GD450B-S | GD600B-S | GD1200B-S |

| Capacity | 150kg/h | 300kg/h | 450kg/h | 600kg/h | 1200kg/h |

| Depositing speed | 25-35n/min | 30-60n/min | |||

| Steam requirement | 250kg/h,0.5-0.8MPa | 300kg/h, 0.5-0.8MPa | 400kg/h, 0.5-0.8MPa | 500kg/h,0.5-0.8MPa | 1200kg/h,0.5-0.8MPa |

| Compressed air requirement | 0.2m3/min, 0.4-0.6MPa | 0.2m3/min, 0.4-0.6MPa | 0.2m3/min, 0.4-0.6MPa | 0.3m3/min, 0.4-0.6MPa | 0.6m3/min, 0.4-0.6MPa |

| Working condition | Temperature 20°C-25°C; Humidity45-55% | ||||

| Electric power needed | 18kW/380V | 27kW/380V | 34kW/380V | 38kW/380V | 56kw/380V |

| Total length | 17m | 19m | 19m | 22m | 40m |

| Weight of machine | 4000kg | 5000kg | 6000kg | 7000kg | 12000kg |

The Market Targeted by Hard Candy Depositing Line

[su_list icon="icon: check-circle-o" icon_color="#0aa5a5"]- Candy Manufacturers

- Food Processing Plants

- Snack Brand Chains

- Independent Entrepreneurs

- OEM

[/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column][/su_row]

[/su_column][/su_row]

Quality Advantage of Candy Depositing Line

[su_accordion] [su_spoiler title="High Automation Level" open="yes" style="fancy"] The whole line is equipped with intelligent control system, and the key parts are equipped with Schneider electrical components and Emerson frequency converter to realize stable operation and precise control. [/su_spoiler] [su_spoiler title="Flexible Molding Options" style="fancy"] Double-color hopper with Italy/Japan original electromagnetic flavor pump and multiple sets of mixers can easily realize the appearance of striped candy, spray candy, double-color candy and other artistic candy.[/su_spoiler] [su_spoiler title="Superior Candy Texture" style="fancy"] Using vacuum film sugar boiling machine and frequency conversion speed control boiling process, the sugar body structure is more compact, the taste is more crisp and the appearance is more shiny. [/su_spoiler] [su_spoiler title="Efficient Cooling" style="fancy"] The 11-meter air-cooled tunnel is equipped with a vibrating screen conveying system, which effectively prevents deformation and maintains the perfect shape and accurate stick position of lollipops. [/su_spoiler] [su_spoiler title="Easy Operation & Maintenance" style="fancy"] The structure is straight and concise, and the mold is easy to change. All the equipment supports customized services, which can meet the production needs of different customers.[/su_spoiler] [su_spoiler title="Global Standard Compliance" style="fancy"] The whole line equipment is designed and manufactured according to international food safety standards (GMP/HACCP), which not only meets the global market supervision requirements, but also helps enterprises to successfully pass various certifications and improve brand reputation.[/su_spoiler] [/su_accordion] [su_row][su_column size="1/3"] [/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column][/su_row]

[/su_column][/su_row]

Recommended Supporting Machines

In order to build a complete and efficient candy production line, it is recommended that you pay attention to the following equipment at the same time:- Lollipop Forming Machine

- Jacketed Kettle

- Premade Pouch Packing Machine

[su_service title="Contact Gondor Machinery" icon="icon: edit" icon_color="#0aa5a5" size="20"][/su_service]

[wpforms id="527" description="true"]

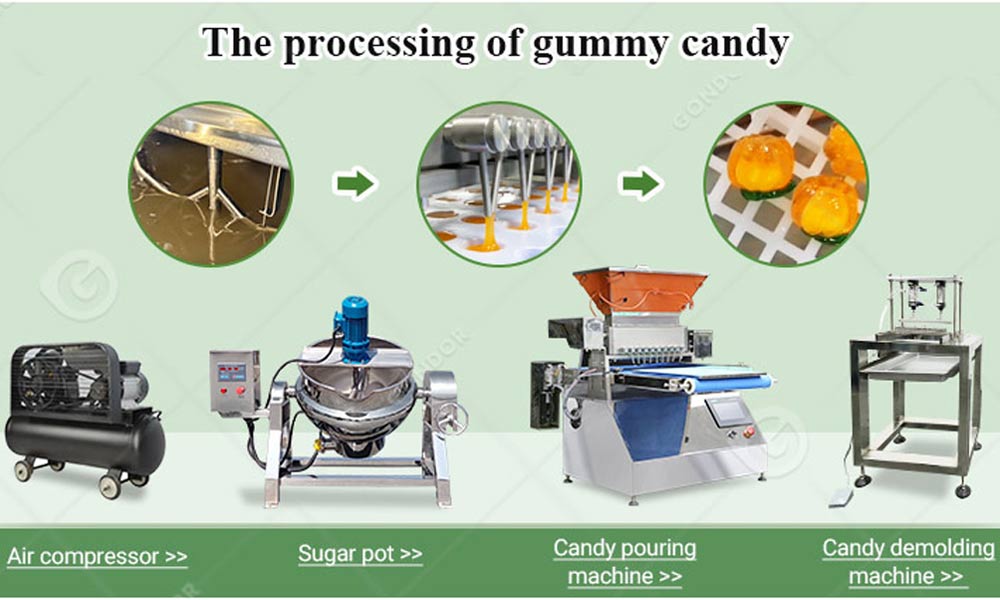

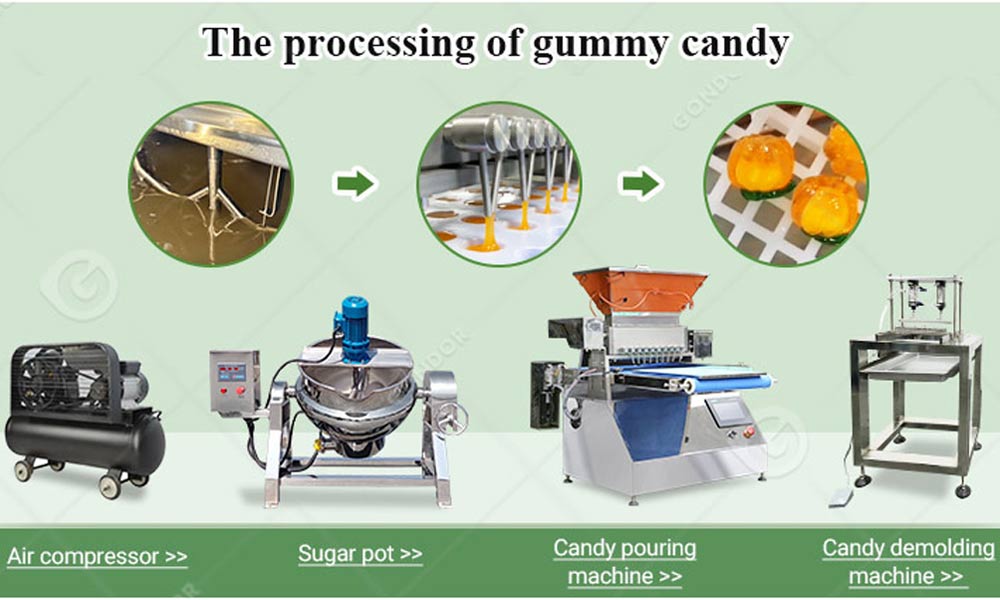

Want to create explosive gummy products? Choose our efficient and intelligent gummy production line to bring you a one-stop solution. The production line integrates raw material treatment, precise blending, mold forming, rapid cooling, demoulding beautification and diverse packaging, realizing real automation and intelligent production. At the same time, the system adopts advanced PLC control system for intelligent control, and the pouring speed can reach 30–45 N/min, which is suitable for efficient customized production of single color, double color, multi-color and sandwich soft candy. Whether you are facing the snack market or are committed to developing functional soft sweets with vitamins or collagen, the gummy making machine can flexibly meet different needs.

[su_row][su_column] [/su_column]

[su_column]

[/su_column]

[su_column] [/su_column][/su_row]

[/su_column][/su_row]

[/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column][/su_row]

[/su_column][/su_row]

[/su_column]

[su_column]

[/su_column]

[su_column] [/su_column][/su_row]

[/su_column][/su_row]

Applicable Fields of Gummy Production Line

[su_tabs style="modern-blue"] [su_tab title="Retail Food" disabled="no" anchor="" url="" target="blank" class=""]It is suitable for producing a variety of soft sweets used in supermarkets and gift markets.[/su_tab] [su_tab title="Health Care Industry" disabled="no" anchor="" url="" target="blank" class=""]It is widely used in the processing of soft sweets with healthy formulas such as probiotics, collagen, vitamins & minerals.[/su_tab] [su_tab title="OEM Brand Manufacturing" disabled="no" anchor="" url="" target="blank" class=""]Providing customized production solutions for brand customers.[/su_tab] [/su_tabs] [su_row][su_column size="1/3"] [/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column]

[su_column size="1/3"]

[/su_column]

[su_column size="1/3"] [/su_column][/su_row]

[/su_column][/su_row]

Technology and Advantages of Gummy Bear Production Line

[su_accordion] [su_spoiler title="Accurate Depositing System" open="yes" style="fancy"] Servo motor control is adopted, so that syrup filling is stable, the quantity is accurate, and each soft candy can be controlled and adjusted. [/su_spoiler] [su_spoiler title="Customizable Molds" style="fancy"] Support a variety of patterns and structural designs to meet customers' diverse appearance requirements. [/su_spoiler] [su_spoiler title="Efficient Cooking System" style="fancy"] The jacketed pot is heated by steam, so that the sugar solution can melt quickly and is not easy to crystallize, thus improving the efficiency. [/su_spoiler] [su_spoiler title="Air Cooling Tunnel" style="fancy"] Built-in brush and air blowing system help candy to set quickly and demould easily. [/su_spoiler] [su_spoiler title="Easy Maintenance" style="fancy"]If the temperature sensor fails, only the plug part needs to be replaced to reduce the maintenance cost.[/su_spoiler] [su_spoiler title="Automation of the Whole Line" style="fancy"] From gel melting tank to syrup mixing tank to oil spraying & polishing system, the whole line has a scientific and compact layout, saving space and improving operation efficiency. Support diversified packaging such as bags and boxes, which perfectly meets the market trend. [/su_spoiler] [/su_accordion] [su_image_carousel source="media: 614,615,616,617,618" controls_style="light" columns="2" align="center"]Explore More Intelligent Candy Equipment Solutions

In order to meet the diversified production needs, we not only provide gummy production line, but also launch a variety of high-performance equipment: [su_list icon="icon: check" icon_color="#0aa5a5"]- Chocolate Coating Machine: It is suitable for oil spraying, anti-sticking and polishing on the surface of soft candy to improve the appearance and taste of products. It is widely used for post-treatment of pectin, gelatin soft candy and functional candy.

- Candy Depositing Machine: It flexibly supports a variety of syrup formulations and filling processes, and is suitable for producing many types of sweets such as hard candy, sandwich candy and milk candy, and has the advantages of accurate quantification and adjustable molds.

- Packaging Solutions: Provide a variety of candy packaging models, support pillow bags, boxes, zipper bags, etc., to meet the diverse packaging needs of retail and gift markets.

[su_service title="Contact Gondor Machinery" icon="icon: edit" icon_color="#0aa5a5" size="20"][/su_service]

[wpforms id="527" description="true"]

3D gummy candy production line integrates raw material treatment, sugar liquid cooking, ingredient blending, precise pouring, rapid cooling, automatic demoulding, and diverse packaging. The whole line is suitable for producing single-color gummy candies, two-color gummy candies, sandwich gummy candies, and gel-filled gummy candies with exploding effects. By supporting mold customization, you can easily create a variety of 3D, brand-specific shapes or festival-themed candy, and truly realize "multi-purpose" and "ever-changing customization".

[/su_column]

[su_column size="1/4"]

[/su_column]

[su_column size="1/4"] [/su_column]

[su_column size="1/4"]

[/su_column]

[su_column size="1/4"] [/su_column]

[su_column size="1/4"]

[/su_column]

[su_column size="1/4"] [/su_column][/su_row]

[/su_column][/su_row]

| Model | GD-150 | GD-300 | GD-450 | HQ-600 |

| Standard production volume(kg/hour) | 150 | 300 | 450 | 600 |

| The sugar weight | 2-6g | 2-6g | 2-6g | 2-6g |

| Pouring rate | 30-35n/min | 45-55n/min | 45-55n/min | 45-55n/min |

| Work environment requirements | Temperature:20-25℃ humidity:55% | |||

| Overall weight | 3800kg | 4000kg | 4500kg | 5000kg |

| Overall length | 15.8m | 17m | 17m | 20m |

Target Market of Gummy Candy Production Line

[su_row][su_column][su_service title="Nutritional Supplements Market" icon="icon: caret-right" icon_color="#0aa5a5" size="20"][/su_service]

It can produce functional soft candy containing vitamins, minerals, collagen, probiotics, and other ingredients, which conforms to the global health trend.

[/su_column]

[su_column]

[su_service title="Creative & OEM" icon="icon: caret-right" icon_color="#0aa5a5" size="20"][/su_service]

It is suitable for customizing personalized soft candy for brands, supporting small-batch diversified production, and meeting the needs of personalized and creative candy.

[/su_column][/su_row]

[su_row][su_column size="1/3"]

[su_service title="Food Market" icon="icon: caret-right" icon_color="#0aa5a5" size="20"][/su_service]

It is suitable for the production of children's candy, holiday gift candy, retail fun soft candy, and other mass consumption products, with a novel appearance and strong attraction.

[/su_column]

[su_column size="1/3"]

[su_service title="Pharmaceutical Applications " icon="icon: caret-right" icon_color="#0aa5a5" size="20"][/su_service]

Support the production of pharmaceutical-grade soft candy, such as children's medicinal chewing candy, sleep-helping soft candy, etc., with accurate dosage and convenient administration.

[/su_column]

[su_column size="1/3"]

[su_service title="Global Market" icon="icon: caret-right" icon_color="#0aa5a5" size="20"][/su_service]

It conforms to the food laws and regulations of many countries, is suitable for export and overseas factory application, and meets the market tastes and packaging standards in different regions.

[/su_column][/su_row]

[su_row][su_column size="1/4"] [/su_column]

[su_column size="1/4"]

[/su_column]

[su_column size="1/4"] [/su_column]

[su_column size="1/4"]

[/su_column]

[su_column size="1/4"] [/su_column]

[su_column size="1/4"]

[/su_column]

[su_column size="1/4"] [/su_column][/su_row]

[/su_column][/su_row]

Competitive Advantage of Gummy Production Equipment

[su_accordion] [su_spoiler title="Multifunctional Integration" open="yes" style="fancy"] A production line covers the whole process of glue melting, sugar melting, blending, quantitative pouring, cooling, demoulding, oil spraying, polishing, and packaging, which helps you save labor and improve efficiency.[/su_spoiler] [su_spoiler title="Precision Deposition System" style="fancy"] The pouring speed reaches 30–45 N/min. Servo motor PLC control and temperature sensor ensure accurate molding, stable operatio,n and convenient maintenance.[/su_spoiler] [su_spoiler title="Fully Customizable Molds" style="fancy"] Support 3D molds, metal molds, and other materials, and customize any pattern to meet the design requirements of creative products.[/su_spoiler] [su_spoiler title="Efficient Cooking System" style="fancy"] Equipped with a jacketed pot and a liquid storage tank, Steam Heating is adopted, so that the syrup is evenly dissolved, fully mixed, quickly heated, energy-saving, and efficient. [/su_spoiler] [su_spoiler title="Cooling & Demolding System" style="fancy"] Air-cooled brush and double pneumatic demoulding combined with an oil injection anti-sticking system help the soft candy to demould quickly, take it out without damage, clean and convenient. [/su_spoiler] [su_spoiler title="Post-processing Capabilities" style="fancy"] It has the processing functions of oil spraying and anti-sticking, sand rolling and flavor enhancement, polishing and beautification, etc., and meets the diversified market demand. [/su_spoiler] [/su_accordion] [su_image_carousel source="media: 560,561,562,563" controls_style="light" columns="2" align="center"]Customize Your Own Gummy Candy Factory

- Doypack Packing Machine: Realize efficient packaging and support automatic packaging of multi-specifications and types of soft sweets.

- Candy Coating Machine: Add outer wrappers such as sugar powder and acid powder to improve the taste and commodity value of soft candy.

- Multi-Head Scale Batching System: Automatically weigh and combine different soft sweets to realize diversified mixed packaging.

[su_service title="Contact Gondor Machinery" icon="icon: edit" icon_color="#0aa5a5" size="20"][/su_service]

[wpforms id="527" description="true"]

With only one device, you can easily make soft candy, hard candy, toffee, chocolate candy, and lollipop, and the shape and taste can be customized freely-this is our innovative table top gummy depositor! The desktop candy depositor is specially designed for laboratory, small batch production, factory proofing, and personalized customization, which not only has high precision, high efficiency, and high automation, but also is simple to operate. It is controlled by a full servo motor, with a multi-language PLC touch screen and a humanized interface, which can be easily used by users all over the world.

Model

GD-DA

(Pouring type)

GD-DB

(Plunger type)

GD-DC

(Oil heating)

GD-V

(Pouring type)

Deposit Times

30-60times/min

30 times/min

30-60times/min

20-35times/min

Productivity

60-100 kg/h

Pouring volume:

0.5-30g (±0.3)

60-100 kg/h

40-150 kg/h

Voltage

220V/50Hz

220V/50Hz

220V/50Hz

220V/50Hz

Power

4.2kw

4.2kw

4.2kw

1.2kw

Nozzle/Piston

10pcs

10pcs

10pcs

20pcs

Machine Size

1000*760*870mm

800*1100*900mm

1000*760*870mm

804*660*1300mm

Weight

100kg

90kg

100kg

320kg

The Market Targeted by the Table Top Gummy Depositor

[su_tabs]

[su_tab title="Candy Manufacturing Plant" disabled="no" anchor="" url="" target="blank" class=""]The equipment can be used for new product proofing, small batch trial production, or customized order production, accurately control the formula and process, improve research and development efficiency, and quickly respond to market demand.[/su_tab]

[su_tab title="Candy Brands & Retail Stores" disabled="no" anchor="" url="" target="blank" class=""]Suitable for on-site production and display, support personalized molds, create differentiated products, improve customer interaction experience, and help brand building and marketing.[/su_tab]

[su_tab title="Food R&D Labs" disabled="no" anchor="" url="" target="blank" class=""]Used in formula development and functional sugar experiment, it is convenient to adjust the proportion of raw materials, test different pouring conditions, and realize a high-precision and stable test environment.[/su_tab]

[su_tab title="Training Institutions" disabled="no" anchor="" url="" target="blank" class=""]As a teaching demonstration, it shows the technological process of candy production and helps students master modern candy production technology.[/su_tab]

[/su_tabs]

[su_row][su_column size="1/3"][/su_column]

[su_column size="1/3"][/su_column]

[su_column size="1/3"][/su_column][/su_row]

Technical Highlights of Small Scale Candy Depositor

[su_accordion]

[su_spoiler title="Precision Pouring" open="yes" style="fancy"] The minimum pouring amount can be 0.2g, equipped with a suction function, preventing dripping, and the pouring amount and speed can be accurately adjusted.[/su_spoiler]

[su_spoiler title="Mold Customization" style="fancy"] Support the customization of molds with various candy shapes and sizes to meet the needs of personalized product development. [/su_spoiler]

[su_spoiler title="Automatic Cleaning" style="fancy"] Built-in cleaning program, one-button start, easy to solve the problem of sticky sugar residue, and save cleaning time. [/su_spoiler]

[su_spoiler title="High-Temperature Heating" style="fancy"] The hopper is designed with electric heating and an oil interlayer, and the maximum heating reaches 150℃ to ensure the continuous flow of sugar.[/su_spoiler]

[su_spoiler title="Intelligent Control" style="fancy"] Equipped with a Siemens PLC touch screen in Germany, which supports both Chinese and English, is easy to operate, and supports formula storage.[/su_spoiler]

[su_spoiler title="Efficient Transmission" style="fancy"] The servo-controlled conveyor belt has a single/double mode, which is flexible and efficient and improves the efficiency of small batch production. [/su_spoiler]

[/su_accordion]

[su_image_carousel source="media: 575,576,577,578,579" controls_style="light" columns="2" align="center"]

Full Support from Trial Production to Mass Production

Whether you are a newcomer to the candy industry or an enterprise user looking for a high-end candy prototype, this table top gummy depositor is an ideal choice. If you want to know more about the lollipop forming machine, the candy cooling tunnel, and other supporting equipment, please contact us to help you build a complete candy production line.

[su_service title="Contact Gondor Machinery" icon="icon: edit" icon_color="#0aa5a5" size="20"][/su_service]

[wpforms id="527" description="true"]

Read More

In the highly competitive candy industry, efficiency, accuracy, and quality are the magic weapons to win. Lollipop forming machine is an innovative equipment born for this purpose, aiming at completely innovate your lollipop production process. Whether it is a traditional spherical lollipop or a novel and unique whistle stick, this equipment can be easily controlled, bringing you higher productivity, lower cost, and more stable product quality.

Modle

Outer size

Voltage

Powder

Candy size

Ball weight

Capacity

Machine weight

GD-400

100*900*1200mm

220v/380v

1.5kw

18-35mm

6-18g

100-300kg/h

600-800pcs/min

600kg

The Broad Application Market of Lollipop Forming Machine

The ball lollipop forming machine is suitable for candy manufacturing enterprises of different sizes, including:

[su_tabs]

[su_tab title="Food Processing Plants" disabled="no" anchor="" url="" target="blank" class=""]In food processing plants, lollipop molding machine can realize large-scale and continuous production, meet the demand of a large number of orders, ensure the consistency of product size and quality, help enterprises respond to the market quickly and improve the overall production efficiency.[/su_tab]

[su_tab title="Candy Manufacturers" disabled="no" anchor="" url="" target="blank" class=""]For candy manufacturing enterprises, the lollipop forming machine is the key equipment to enhance product diversity and competitiveness. It not only supports the production of lollipops with different tastes and specifications, but also reduces labor costs and achieves higher profit margins.[/su_tab]

[su_tab title="Startups & Entrepreneurs" disabled="no" anchor="" url="" target="blank" class=""]For individual entrepreneurs, a compact and user-friendly lollipop molding machine is ideal for entering the candy market. With low investment and quick learning, even small batches can produce high-quality products, boosting startup success.[/su_tab]

[/su_tabs]

Whether you are in mass production or small batch customization, this equipment can accurately meet your dual requirements of output and quality.

[su_row][su_column size="1/3"][/su_column]

[su_column size="1/3"][/su_column]

[su_column size="1/3"][/su_column][/su_row]

Extraordinary Performance Advantages of Ball Lollipop Forming Machine

[su_accordion]

[su_spoiler title="High Precision & Consistency" open="yes" style="fancy"]

Advanced mechanical design and an intelligent control system are adopted to ensure that the shape, weight, and size of each lollipop are highly consistent.

The sugar wheel can be flexibly adjusted, and the size of the sugar balls can be easily changed to meet diverse market demands.

[/su_spoiler]

[su_spoiler title="Compact Structure" style="fancy"]

The overall design of the equipment is exquisite, and it can operate efficiently even in a limited factory space.

[/su_spoiler]

[su_spoiler title="Hygienic & Easy Cleaning" style="fancy"] All parts in contact with raw materials are made of food-grade SUS 304 stainless steel, which is rust-proof, corrosion-proof, simple to clean, and meets international food hygiene standards. [/su_spoiler]

[su_spoiler title="High Production Capacity" style="fancy"]The lollipop forming machine has high production efficiency, which can greatly increase the output and help enterprises meet the market demand quickly.[/su_spoiler]

[su_spoiler title="Multiple Flavors & Shapes" style="fancy"] Can produce a variety of flavors and types of lollipops, from traditional tastes to customized features, to meet the individual needs of different customers. [/su_spoiler]

[su_spoiler title="High Automation Level" style="fancy"] The machine is equipped with an intelligent control panel, with a friendly interface and simple operation, which reduces the dependence on operators and greatly reduces labor costs.[/su_spoiler]

[su_spoiler title="Low Noise Operation" style="fancy"] The pressing wheel has excellent design, stable operation, extremely low noise, and an optimized production environment. [/su_spoiler]

[/su_accordion]

[su_row][su_column size="1/3"][/su_column]

[su_column size="1/3"][/su_column]

[su_column size="1/3"][/su_column][/su_row]

More Intelligent Candy Equipment Will Help You Upgrade the Whole Line

In addition to a lollipop forming machine, we also provide a range of high-end candy production equipment, including a candy depositor machine, a chocolate coating machine, and packaging machines, to help you create an integrated solution from production to packaging. If you need more candy production equipment, please contact our professional team, and we will provide you with tailor-made and efficient production solutions!

[su_service title="Contact Gondor Machinery" icon="icon: edit" icon_color="#0aa5a5" size="20"][/su_service]

[wpforms id="527" description="true"]

Read More

With the increasing demand for product diversification, quality stability and automation efficiency in the global candy market, the hard candy depositing line independently developed by our company came into being. Combined with many years' experience in food machinery manufacturing, the production line adopts international advanced automation technology, which is specially designed for producing high-quality hard candy with multi-color and multi-morphology. Moreover, the whole line is composed of core equipment such as sugar boiling pot, syrup storage tank, vacuum film sugar boiling machine, hard candy pouring machine and air-cooled tunnel. It is compact in structure and easy to operate. It is made of food-grade stainless steel and meets international standards such as GMP/HACCP/QS. In addition, by changing the mold flexibly, single color, two color, three color sugar, crystal sugar, button sugar and spherical lollipop can be produced efficiently, which fully meets the diversified market demand.

Model

GD150B-S

GD300B-S

GD450B-S

GD600B-S

GD1200B-S

Capacity

150kg/h

300kg/h

450kg/h

600kg/h

1200kg/h

Depositing speed

25-35n/min

30-60n/min

Steam requirement

250kg/h,0.5-0.8MPa

300kg/h,

0.5-0.8MPa

400kg/h,

0.5-0.8MPa

500kg/h,0.5-0.8MPa

1200kg/h,0.5-0.8MPa

Compressed air requirement

0.2m3/min,

0.4-0.6MPa

0.2m3/min,

0.4-0.6MPa

0.2m3/min,

0.4-0.6MPa

0.3m3/min,

0.4-0.6MPa

0.6m3/min,

0.4-0.6MPa

Working condition

Temperature 20°C-25°C; Humidity45-55%

Electric power needed

18kW/380V

27kW/380V

34kW/380V

38kW/380V

56kw/380V

Total length

17m

19m

19m

22m

40m

Weight of machine

4000kg

5000kg

6000kg

7000kg

12000kg

The Market Targeted by Hard Candy Depositing Line

[su_list icon="icon: check-circle-o" icon_color="#0aa5a5"]

Candy Manufacturers

Food Processing Plants

Snack Brand Chains

Independent Entrepreneurs

OEM

[/su_list]

Whether it is a large-scale automatic factory or a small and medium-sized food enterprise, Gondor hard candy making machine can help you stand out in the candy market with flexible configuration and reliable performance.

[su_row][su_column size="1/3"][/su_column]

[su_column size="1/3"][/su_column]

[su_column size="1/3"][/su_column][/su_row]

Quality Advantage of Candy Depositing Line

[su_accordion]

[su_spoiler title="High Automation Level" open="yes" style="fancy"] The whole line is equipped with intelligent control system, and the key parts are equipped with Schneider electrical components and Emerson frequency converter to realize stable operation and precise control. [/su_spoiler]

[su_spoiler title="Flexible Molding Options" style="fancy"] Double-color hopper with Italy/Japan original electromagnetic flavor pump and multiple sets of mixers can easily realize the appearance of striped candy, spray candy, double-color candy and other artistic candy.[/su_spoiler]

[su_spoiler title="Superior Candy Texture" style="fancy"] Using vacuum film sugar boiling machine and frequency conversion speed control boiling process, the sugar body structure is more compact, the taste is more crisp and the appearance is more shiny. [/su_spoiler]

[su_spoiler title="Efficient Cooling" style="fancy"] The 11-meter air-cooled tunnel is equipped with a vibrating screen conveying system, which effectively prevents deformation and maintains the perfect shape and accurate stick position of lollipops. [/su_spoiler]

[su_spoiler title="Easy Operation & Maintenance" style="fancy"] The structure is straight and concise, and the mold is easy to change. All the equipment supports customized services, which can meet the production needs of different customers.[/su_spoiler]

[su_spoiler title="Global Standard Compliance" style="fancy"] The whole line equipment is designed and manufactured according to international food safety standards (GMP/HACCP), which not only meets the global market supervision requirements, but also helps enterprises to successfully pass various certifications and improve brand reputation.[/su_spoiler]

[/su_accordion]

[su_row][su_column size="1/3"][/su_column]

[su_column size="1/3"][/su_column]

[su_column size="1/3"][/su_column][/su_row]

Recommended Supporting Machines

In order to build a complete and efficient candy production line, it is recommended that you pay attention to the following equipment at the same time:

Lollipop Forming Machine

Jacketed Kettle

Premade Pouch Packing Machine

Whether you are expanding your business or seeking more advanced production solutions, hard candy depositing line is your solid backing to win the market. Welcome to contact us for more technical data and quotation information, and we will tailor the best solution for you.

[su_service title="Contact Gondor Machinery" icon="icon: edit" icon_color="#0aa5a5" size="20"][/su_service]

[wpforms id="527" description="true"]

Read More

Want to create explosive gummy products? Choose our efficient and intelligent gummy production line to bring you a one-stop solution. The production line integrates raw material treatment, precise blending, mold forming, rapid cooling, demoulding beautification and diverse packaging, realizing real automation and intelligent production. At the same time, the system adopts advanced PLC control system for intelligent control, and the pouring speed can reach 30–45 N/min, which is suitable for efficient customized production of single color, double color, multi-color and sandwich soft candy. Whether you are facing the snack market or are committed to developing functional soft sweets with vitamins or collagen, the gummy making machine can flexibly meet different needs.

[su_row][su_column][/su_column]

[su_column][/su_column][/su_row]

Applicable Fields of Gummy Production Line

[su_tabs style="modern-blue"]

[su_tab title="Retail Food" disabled="no" anchor="" url="" target="blank" class=""]It is suitable for producing a variety of soft sweets used in supermarkets and gift markets.[/su_tab]

[su_tab title="Health Care Industry" disabled="no" anchor="" url="" target="blank" class=""]It is widely used in the processing of soft sweets with healthy formulas such as probiotics, collagen, vitamins & minerals.[/su_tab]

[su_tab title="OEM Brand Manufacturing" disabled="no" anchor="" url="" target="blank" class=""]Providing customized production solutions for brand customers.[/su_tab]

[/su_tabs]

[su_row][su_column size="1/3"][/su_column]

[su_column size="1/3"][/su_column]

[su_column size="1/3"][/su_column][/su_row]

Technology and Advantages of Gummy Bear Production Line

[su_accordion]

[su_spoiler title="Accurate Depositing System" open="yes" style="fancy"] Servo motor control is adopted, so that syrup filling is stable, the quantity is accurate, and each soft candy can be controlled and adjusted. [/su_spoiler]

[su_spoiler title="Customizable Molds" style="fancy"] Support a variety of patterns and structural designs to meet customers' diverse appearance requirements. [/su_spoiler]

[su_spoiler title="Efficient Cooking System" style="fancy"] The jacketed pot is heated by steam, so that the sugar solution can melt quickly and is not easy to crystallize, thus improving the efficiency. [/su_spoiler]

[su_spoiler title="Air Cooling Tunnel" style="fancy"] Built-in brush and air blowing system help candy to set quickly and demould easily. [/su_spoiler]

[su_spoiler title="Easy Maintenance" style="fancy"]If the temperature sensor fails, only the plug part needs to be replaced to reduce the maintenance cost.[/su_spoiler]

[su_spoiler title="Automation of the Whole Line" style="fancy"] From gel melting tank to syrup mixing tank to oil spraying & polishing system, the whole line has a scientific and compact layout, saving space and improving operation efficiency. Support diversified packaging such as bags and boxes, which perfectly meets the market trend. [/su_spoiler]

[/su_accordion]

[su_image_carousel source="media: 614,615,616,617,618" controls_style="light" columns="2" align="center"]

Explore More Intelligent Candy Equipment Solutions

In order to meet the diversified production needs, we not only provide gummy production line, but also launch a variety of high-performance equipment:

[su_list icon="icon: check" icon_color="#0aa5a5"]

Chocolate Coating Machine: It is suitable for oil spraying, anti-sticking and polishing on the surface of soft candy to improve the appearance and taste of products. It is widely used for post-treatment of pectin, gelatin soft candy and functional candy.

Candy Depositing Machine: It flexibly supports a variety of syrup formulations and filling processes, and is suitable for producing many types of sweets such as hard candy, sandwich candy and milk candy, and has the advantages of accurate quantification and adjustable molds.

Packaging Solutions: Provide a variety of candy packaging models, support pillow bags, boxes, zipper bags, etc., to meet the diverse packaging needs of retail and gift markets.

[/su_list]

By integrating these devices, you can not only increase production capacity, but also expand product categories and market coverage. Contact us immediately to get customized turnkey solution, and start your soft candy brand in one stop!

[su_service title="Contact Gondor Machinery" icon="icon: edit" icon_color="#0aa5a5" size="20"][/su_service]

[wpforms id="527" description="true"]

Read More

3D gummy candy production line integrates raw material treatment, sugar liquid cooking, ingredient blending, precise pouring, rapid cooling, automatic demoulding, and diverse packaging. The whole line is suitable for producing single-color gummy candies, two-color gummy candies, sandwich gummy candies, and gel-filled gummy candies with exploding effects. By supporting mold customization, you can easily create a variety of 3D, brand-specific shapes or festival-themed candy, and truly realize "multi-purpose" and "ever-changing customization".

Model

GD-150

GD-300

GD-450

HQ-600

Standard production volume(kg/hour)

150

300

450

600

The sugar weight

2-6g

2-6g

2-6g

2-6g

Pouring rate

30-35n/min

45-55n/min

45-55n/min

45-55n/min

Work environment requirements

Temperature:20-25℃ humidity:55%

Overall weight

3800kg

4000kg

4500kg

5000kg

Overall length

15.8m

17m

17m

20m

Target Market of Gummy Candy Production Line

[su_row][su_column]

[su_service title="Nutritional Supplements Market" icon="icon: caret-right" icon_color="#0aa5a5" size="20"][/su_service]

It can produce functional soft candy containing vitamins, minerals, collagen, probiotics, and other ingredients, which conforms to the global health trend.

[/su_column]

[su_column]

[su_service title="Creative & OEM" icon="icon: caret-right" icon_color="#0aa5a5" size="20"][/su_service]

It is suitable for customizing personalized soft candy for brands, supporting small-batch diversified production, and meeting the needs of personalized and creative candy.

[/su_column][/su_row]

[su_row][su_column size="1/3"]

[su_service title="Food Market" icon="icon: caret-right" icon_color="#0aa5a5" size="20"][/su_service]

It is suitable for the production of children's candy, holiday gift candy, retail fun soft candy, and other mass consumption products, with a novel appearance and strong attraction.

[/su_column]

[su_column size="1/3"]

[su_service title="Pharmaceutical Applications " icon="icon: caret-right" icon_color="#0aa5a5" size="20"][/su_service]

Support the production of pharmaceutical-grade soft candy, such as children's medicinal chewing candy, sleep-helping soft candy, etc., with accurate dosage and convenient administration.

[/su_column]

[su_column size="1/3"]

[su_service title="Global Market" icon="icon: caret-right" icon_color="#0aa5a5" size="20"][/su_service]

It conforms to the food laws and regulations of many countries, is suitable for export and overseas factory application, and meets the market tastes and packaging standards in different regions.

[/su_column][/su_row]

[su_row][su_column size="1/4"][/su_column]

[su_column size="1/4"][/su_column]

[su_column size="1/4"][/su_column]

[su_column size="1/4"][/su_column][/su_row]

Competitive Advantage of Gummy Production Equipment

[su_accordion]

[su_spoiler title="Multifunctional Integration" open="yes" style="fancy"] A production line covers the whole process of glue melting, sugar melting, blending, quantitative pouring, cooling, demoulding, oil spraying, polishing, and packaging, which helps you save labor and improve efficiency.[/su_spoiler]

[su_spoiler title="Precision Deposition System" style="fancy"] The pouring speed reaches 30–45 N/min. Servo motor PLC control and temperature sensor ensure accurate molding, stable operatio,n and convenient maintenance.[/su_spoiler]

[su_spoiler title="Fully Customizable Molds" style="fancy"] Support 3D molds, metal molds, and other materials, and customize any pattern to meet the design requirements of creative products.[/su_spoiler]

[su_spoiler title="Efficient Cooking System" style="fancy"] Equipped with a jacketed pot and a liquid storage tank, Steam Heating is adopted, so that the syrup is evenly dissolved, fully mixed, quickly heated, energy-saving, and efficient. [/su_spoiler]

[su_spoiler title="Cooling & Demolding System" style="fancy"] Air-cooled brush and double pneumatic demoulding combined with an oil injection anti-sticking system help the soft candy to demould quickly, take it out without damage, clean and convenient. [/su_spoiler]

[su_spoiler title="Post-processing Capabilities" style="fancy"] It has the processing functions of oil spraying and anti-sticking, sand rolling and flavor enhancement, polishing and beautification, etc., and meets the diversified market demand. [/su_spoiler]

[/su_accordion]

[su_image_carousel source="media: 560,561,562,563" controls_style="light" columns="2" align="center"]

Customize Your Own Gummy Candy Factory

Doypack Packing Machine: Realize efficient packaging and support automatic packaging of multi-specifications and types of soft sweets.

Candy Coating Machine: Add outer wrappers such as sugar powder and acid powder to improve the taste and commodity value of soft candy.

Multi-Head Scale Batching System: Automatically weigh and combine different soft sweets to realize diversified mixed packaging.

Whether you want to make nutritious gummy candy, creative gift candy, or launch your own brand of gummy candy, our 3D gummy bear machine can meet the performance, flexibility, and accuracy required by your business. Let your creativity take shape in every candy!

[su_service title="Contact Gondor Machinery" icon="icon: edit" icon_color="#0aa5a5" size="20"][/su_service]

[wpforms id="527" description="true"]

Read More