Gummy Production Line

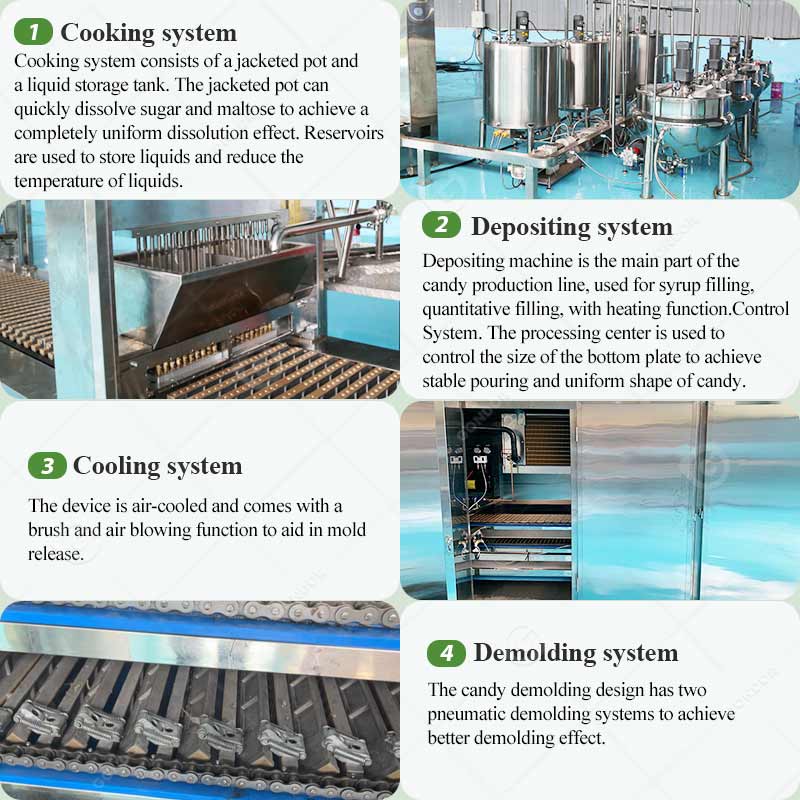

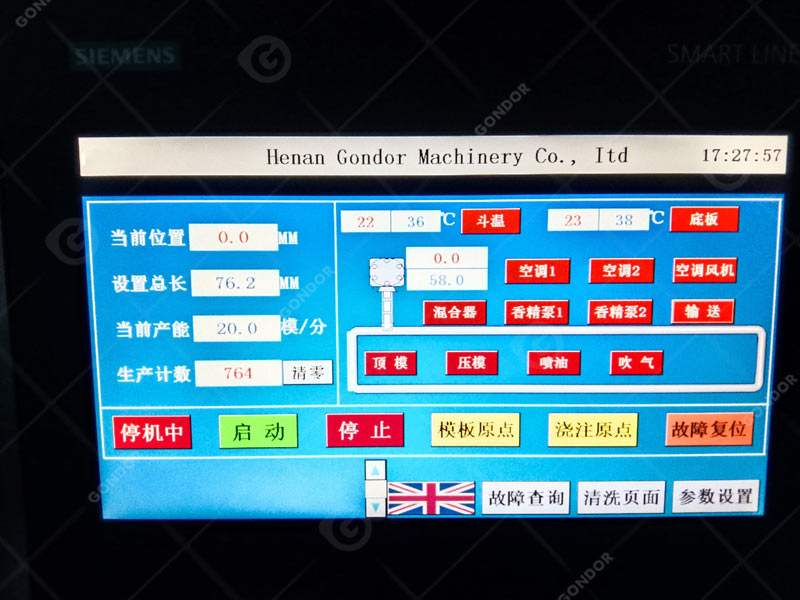

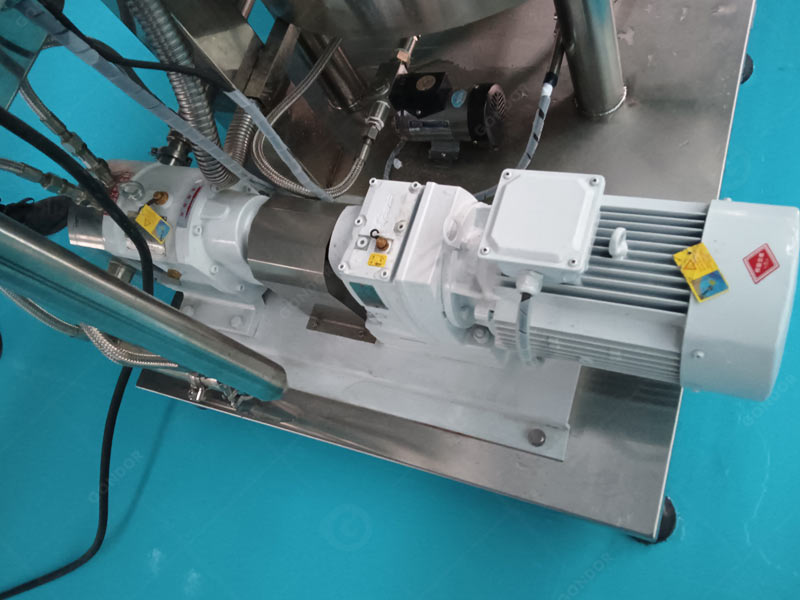

Want to create explosive gummy products? Choose our efficient and intelligent gummy production line to bring you a one-stop solution. The production line integrates raw material treatment, precise blending, mold forming, rapid cooling, demoulding beautification and diverse packaging, realizing real automation and intelligent production. At the same time, the system adopts advanced PLC control system for intelligent control, and the pouring speed can reach 30–45 N/min, which is suitable for efficient customized production of single color, double color, multi-color and sandwich soft candy. Whether you are facing the snack market or are committed to developing functional soft sweets with vitamins or collagen, the gummy making machine can flexibly meet different needs.

Applicable Fields of Gummy Production Line

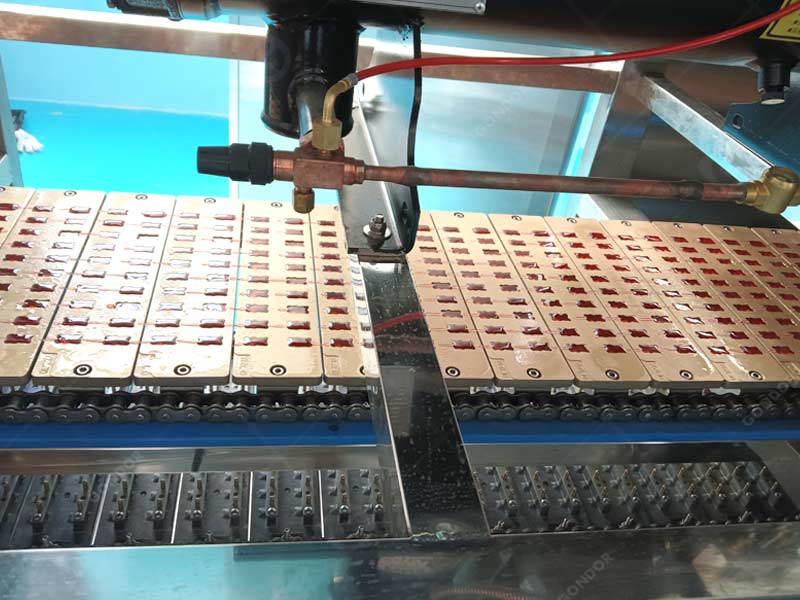

Technology and Advantages of Gummy Bear Production Line

Explore More Intelligent Candy Equipment Solutions

In order to meet the diversified production needs, we not only provide gummy production line, but also launch a variety of high-performance equipment:

- Chocolate Coating Machine: It is suitable for oil spraying, anti-sticking and polishing on the surface of soft candy to improve the appearance and taste of products. It is widely used for post-treatment of pectin, gelatin soft candy and functional candy.

- Candy Depositing Machine: It flexibly supports a variety of syrup formulations and filling processes, and is suitable for producing many types of sweets such as hard candy, sandwich candy and milk candy, and has the advantages of accurate quantification and adjustable molds.

- Packaging Solutions: Provide a variety of candy packaging models, support pillow bags, boxes, zipper bags, etc., to meet the diverse packaging needs of retail and gift markets.