With the increasing global demand for healthy, personalized and efficient candy production, traditional candy production equipment can no longer meet the diversified challenges of the modern market. Both emerging brands and mature multinational food groups have turned their attention to smarter and more efficient candy making machines, gummy machine and gummy counting machine to cope with fierce market competition and consumption upgrading.

Candy Making Machines: Not Just a Machine for “Making Sugar”

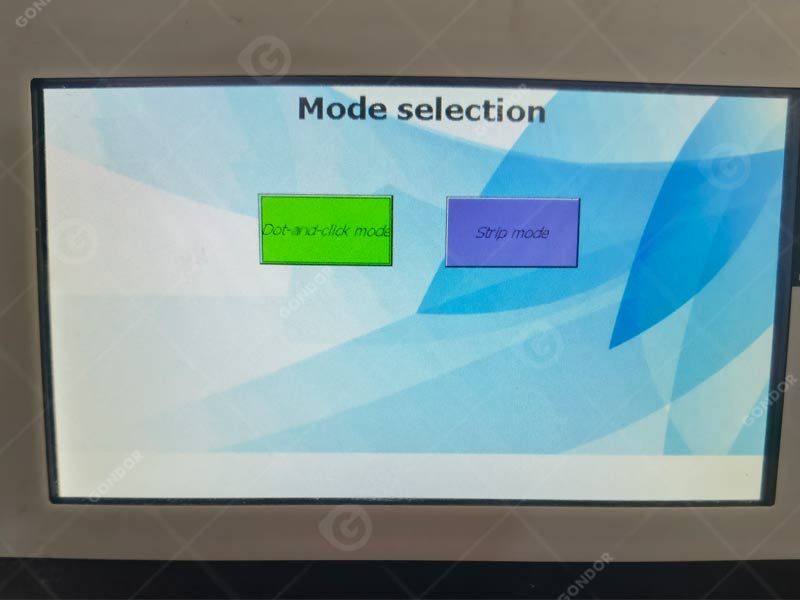

Modern candy making machines have already surpassed the traditional functions of “mixing, molding and cooling”. Nowadays, they integrate automatic control system, precise temperature management, raw material proportioning system and other modules, which can adapt to many candy types, such as hard candy, soft candy, sandwich candy, lollipop and so on.

Trend Highlights

Gummy Machine: The Gummy Craze Sweeps the Globe

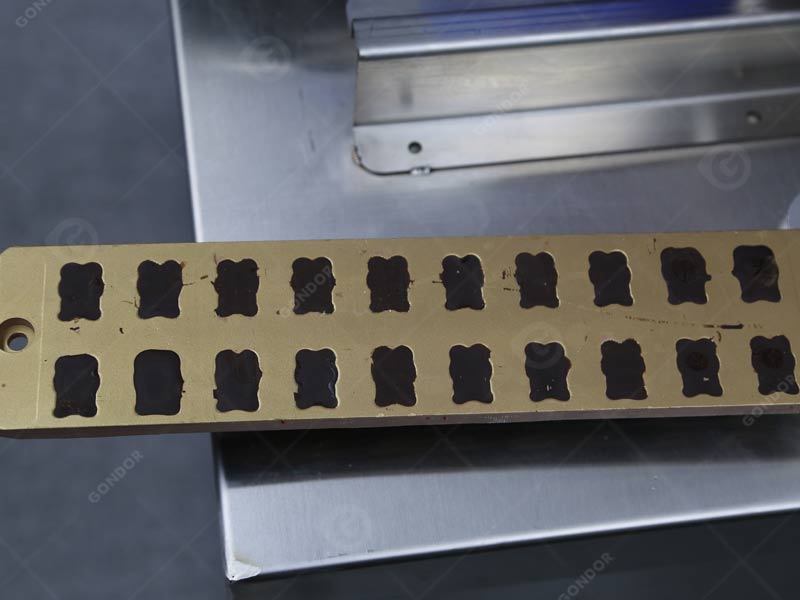

In recent years, gummy machines have emerged as the “star product” in the candy manufacturing industry. Sales of nutritional gummies containing vitamins and functional plant extracts have surged, particularly in North American, European, and Southeast Asian markets.

Core Advantages of Gummy Machines:

Gummy Counting Machine: High-Speed Accurate Packaging

In the packaging process, the traditional manual sorting method can no longer meet the dual requirements of high-speed shipment and food safety. This is why more and more manufacturers invest in upgrading gummy counting machine.

Candy Making Machines: Start, Then More Automation

If your candy business is facing problems such as productivity bottleneck, low packaging efficiency and unstable products, it is time to re-examine your equipment system.

- Pouch Filling and Sealing Machine

- Ball Lollipop Forming Machine

- Marshmallow Maker Machine