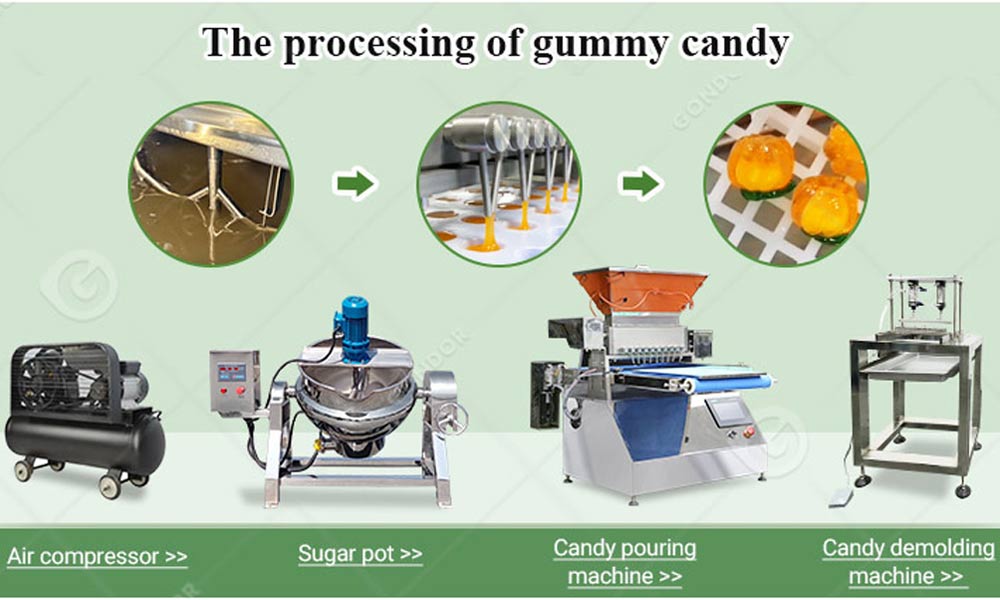

Gondor Table Top Gummy Depositor Introduction

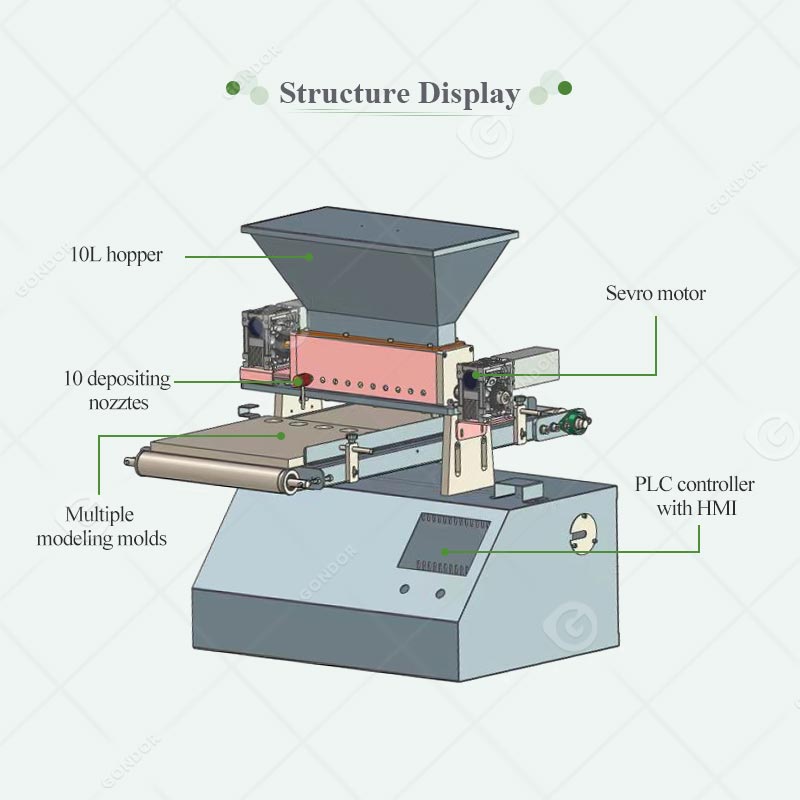

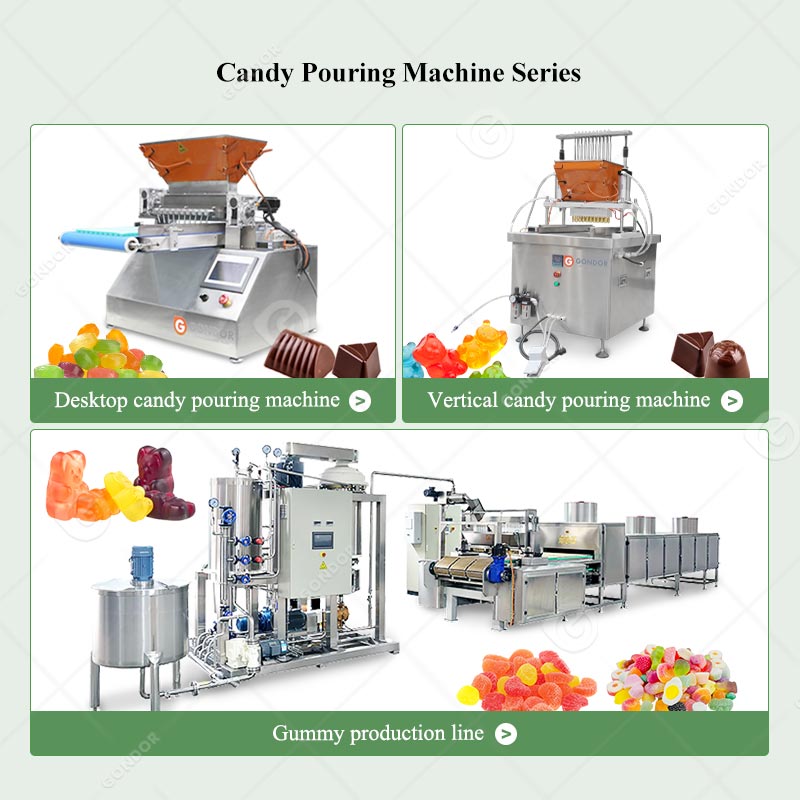

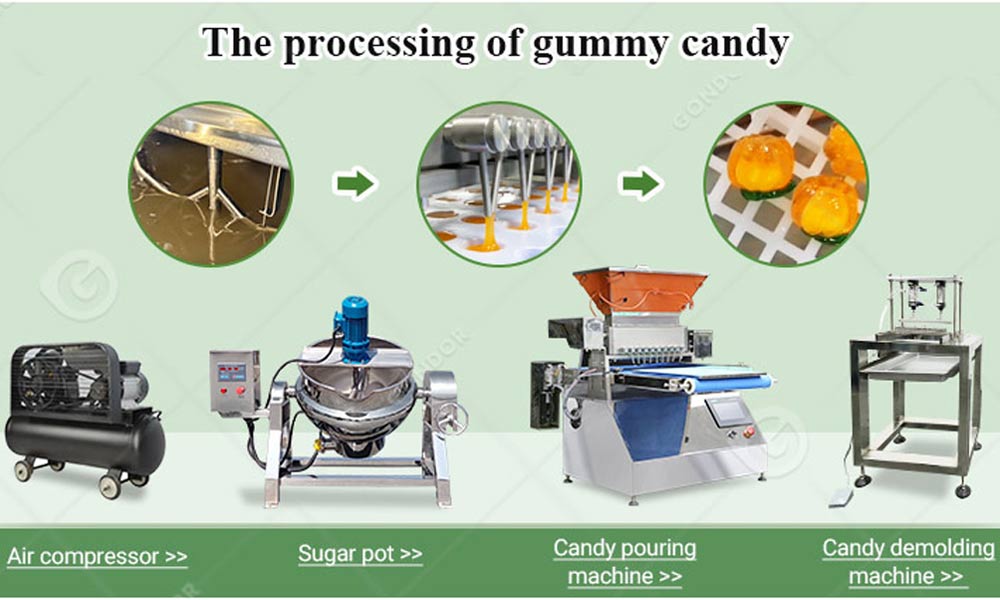

With only one device, you can easily make soft candy, hard candy, toffee, chocolate candy, and lollipop, and the shape and taste can be customized freely-this is our innovative table top gummy depositor! The desktop candy depositor is specially designed for laboratory, small batch production, factory proofing, and personalized customization, which not only has high precision, high efficiency, and high automation, but also is simple to operate. It is controlled by a full servo motor, with a multi-language PLC touch screen and a humanized interface, which can be easily used by users all over the world.

Gondor Table Top Gummy Depositor Models

| Model |

GD-DA

(Pouring Type) |

GD-DB

(Plunger Type) |

GD-DC

(Oil Heating) |

GD-V

(Pouring Type) |

| Deposit Times |

30-60times/min |

30 times/min |

30-60times/min |

20-35times/min |

| Productivity |

60-100 kg/h |

Pouring Volume:

0.5-30g (±0.3) |

60-100 kg/h |

40-150 kg/h |

| Voltage |

220V/50Hz |

| Power |

4.2kw |

1.2kw |

| Nozzle/Piston |

10pcs |

20pcs |

| Machine Size |

1000*760*870mm |

800*1100*900mm |

1000*760*870mm |

804*660*1300mm |

| Weight |

100kg |

90kg |

100kg |

320kg |

The Market Targeted by the Table Top Gummy Depositor

Candy Manufacturing PlantCandy Brands & Retail StoresFood R&D LabsTraining Institutions

The equipment can be used for new product proofing, small batch trial production, or customized order production, accurately control the formula and process, improve research and development efficiency, and quickly respond to market demand.

Suitable for on-site production and display, support personalized molds, create differentiated products, improve customer interaction experience, and help brand building and marketing.

Used in formula development and functional sugar experiment, it is convenient to adjust the proportion of raw materials, test different pouring conditions, and realize a high-precision and stable test environment.

As a teaching demonstration, it shows the technological process of candy production and helps students master modern candy production technology.

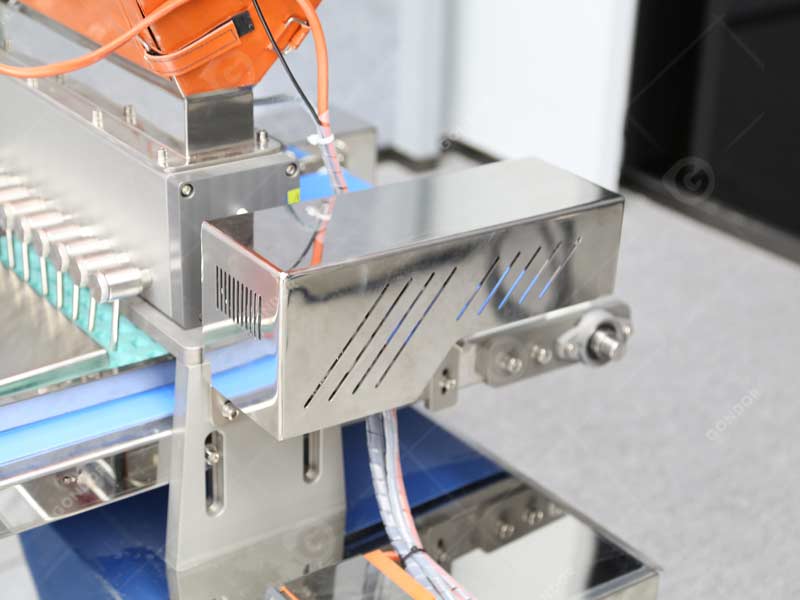

Technical Highlights of Small Scale Candy Depositor

Precision Pouring

The minimum pouring amount can be 0.2g, equipped with a suction function, preventing dripping, and the pouring amount and speed can be accurately adjusted.

Mold Customization

Support the customization of molds with various candy shapes and sizes to meet the needs of personalized product development.

Automatic Cleaning

Built-in cleaning program, one-button start, easy to solve the problem of sticky sugar residue, and save cleaning time.

High-Temperature Heating

The hopper is designed with electric heating and an oil interlayer, and the maximum heating reaches 150℃ to ensure the continuous flow of sugar.

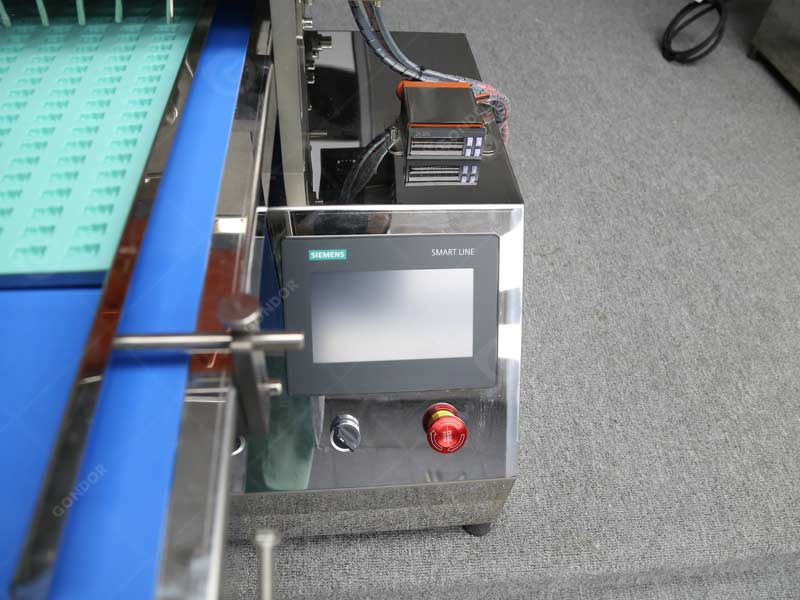

Intelligent Control

Equipped with a Siemens PLC touch screen in Germany, which supports both Chinese and English, is easy to operate, and supports formula storage.

Efficient Transmission

The servo-controlled conveyor belt has a single/double mode, which is flexible and efficient and improves the efficiency of small batch production.

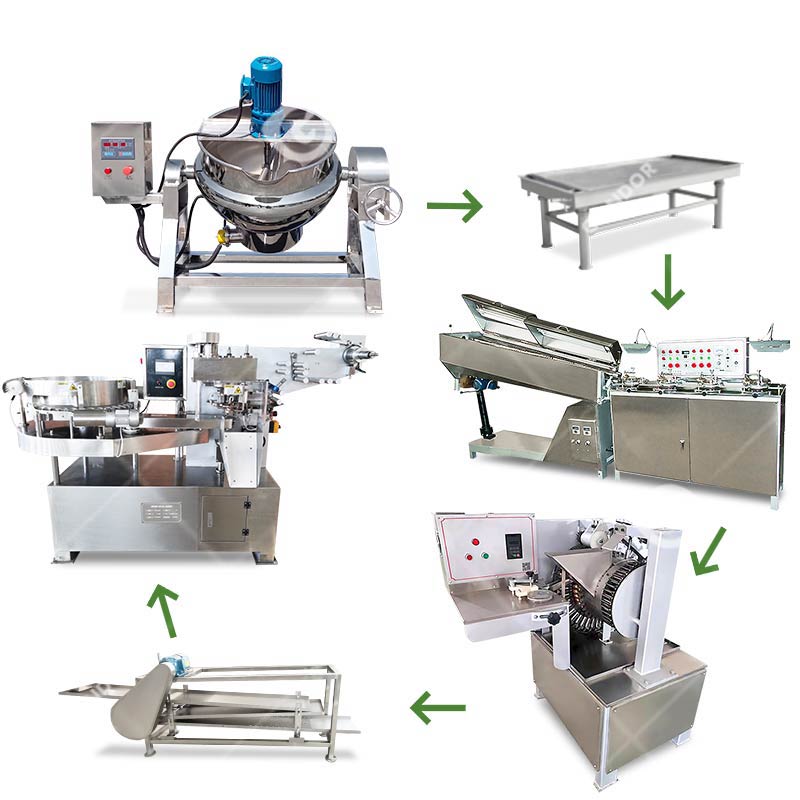

Full Support from Trial Production to Mass Production

Whether you are a newcomer to the candy industry or an enterprise user looking for a high-end candy prototype, this table top gummy depositor is an ideal choice. If you want to know more about the lollipop forming machine, the candy cooling tunnel, and other supporting equipment, please contact us to help you build a complete candy production line.