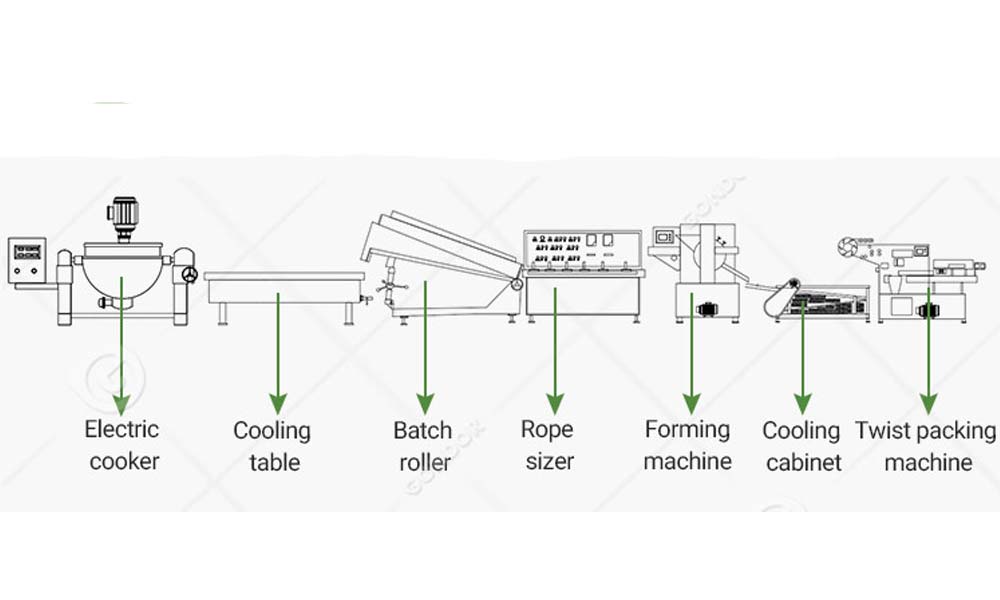

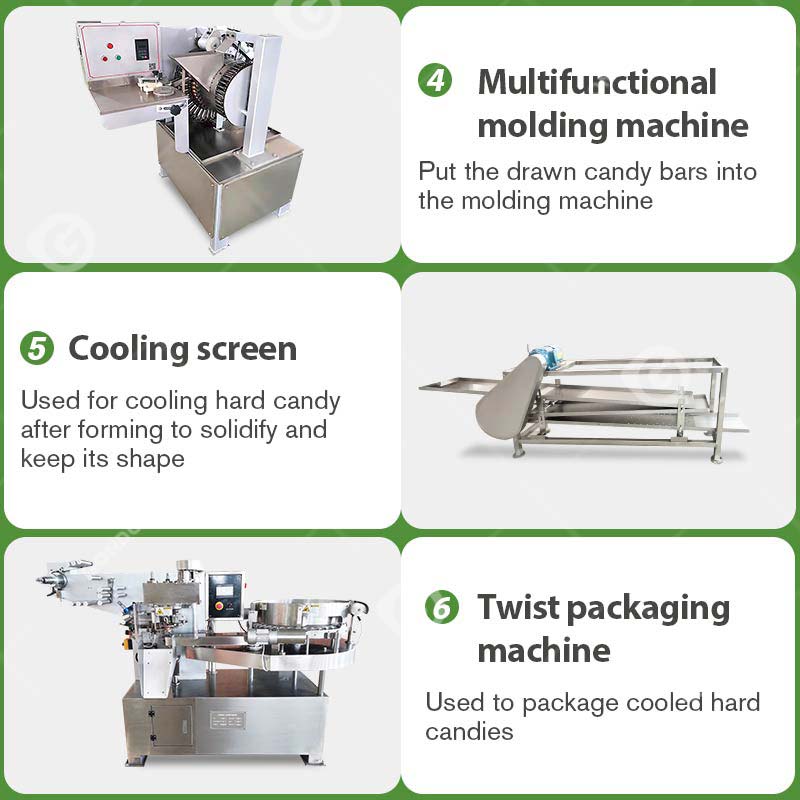

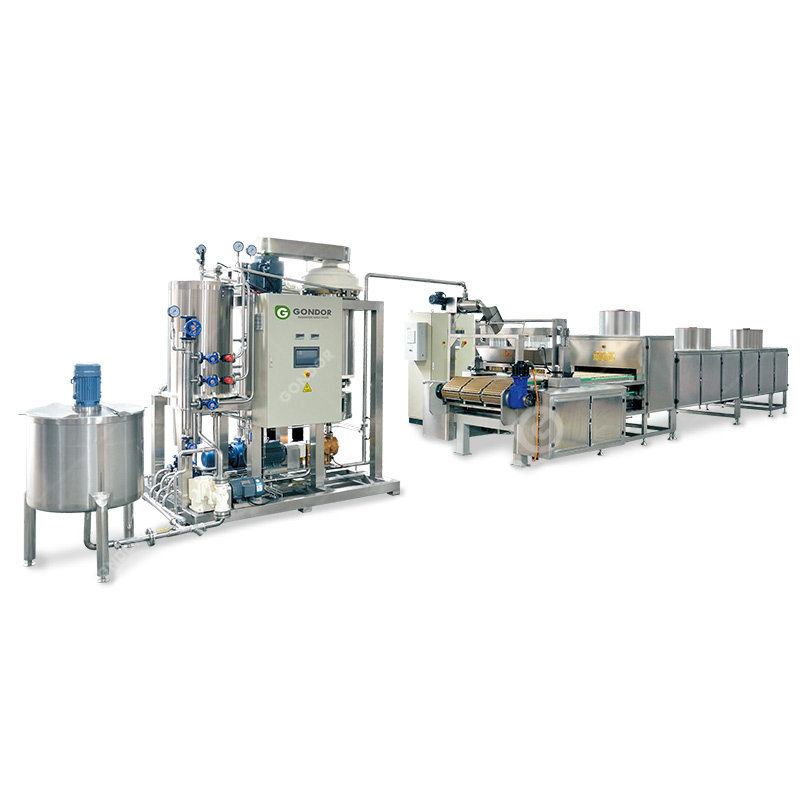

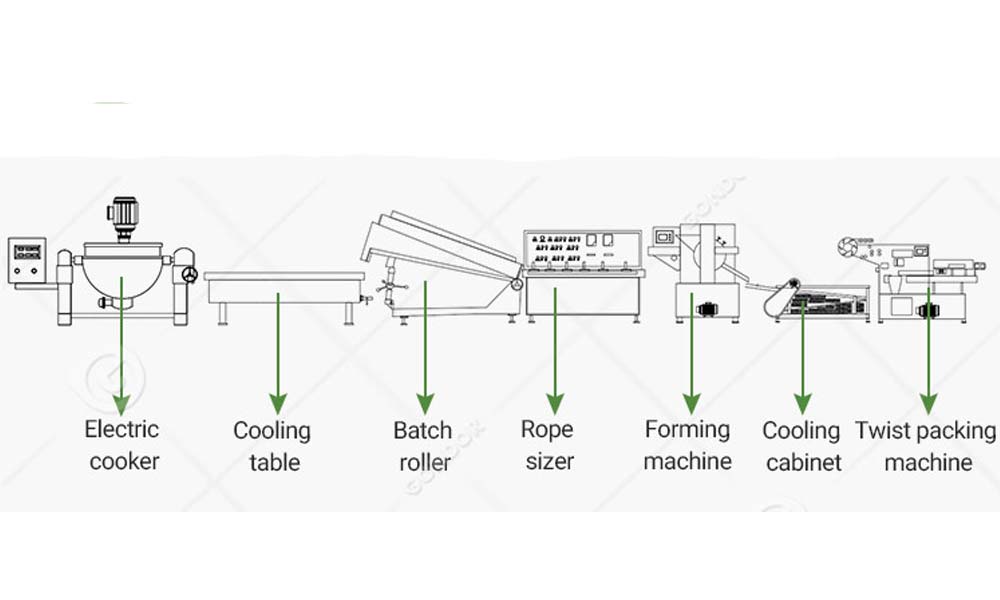

Moulded hard candy production line is an efficient, automatic and multifunctional candy forming equipment, which integrates a thermal insulation roller and a drawing machine, with compact structure, simple operation and stable performance. Therefore, it is very suitable for the candy industry to realize standardization and large-scale production. The whole line includes a sugar boiling pot, a cooling table, a heat preservation roller, a drawing machine, a molding machine, a cooling screen, and a packaging machine. It is suitable for producing transparent candy, fruit candy, sandwich candy, and strong candy. The final product has crystal clear appearance, accurate molding and reliable quality.

| Name |

Power (kW) |

Voltage(v) |

Weight (kg) |

Size (mm) |

Capacity (kg/h) |

| Sugar boiler |

15 |

220/380 |

153 |

1480*900*1290 |

100-140 |

| Cooling table |

/ |

/ |

235 |

2000*1000*600 |

500 |

| Roller and strip machine |

6.3 |

220/380 |

720 |

3800*650*1600 |

400 |

| Forming machine |

3 |

520 |

1100*900*1200 |

600 |

| Vibrating screen |

0.75 |

150 |

2200*450*600 |

700 |

| Packaging machine |

2.1 |

900 |

2300*920*1520 |

900 |

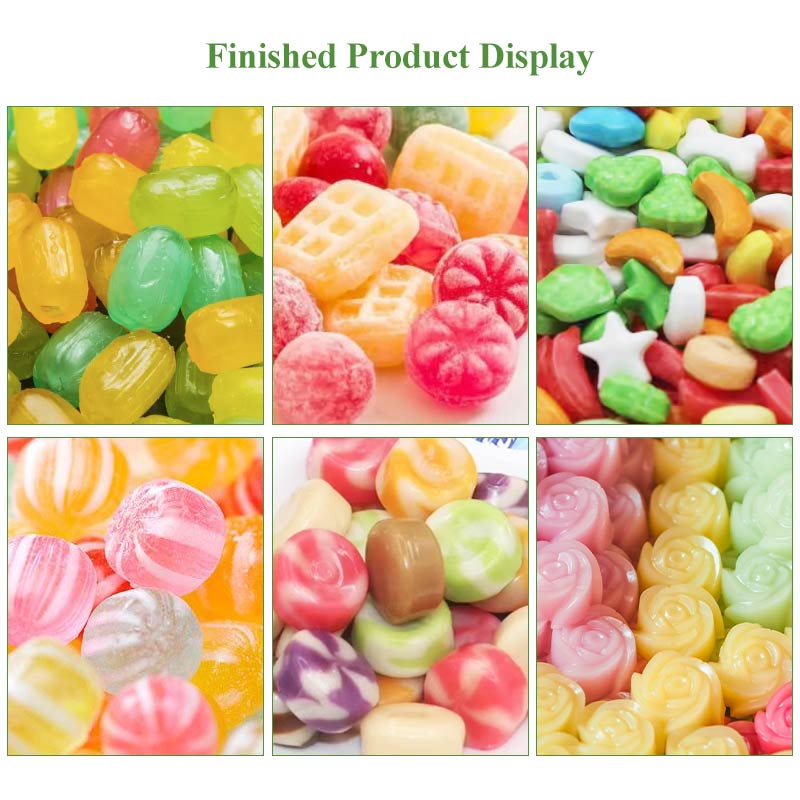

Application and Production Types of Hard Candy Production Line

- Clear Hard Candy

- Center-filled Candy

- Dual-color Striped Candy

- Fruit-flavored Candy

- Sugar-free Candy

- Cream Candy

It not only meets the needs of the mass consumer market, but also supports high-end customization, helping brands to expand diversified product lines.

Remarkable Competitive Advantage of Hard Candy Equipment

High Automation

The full production line realizes PLC control system, and with LED touch screen operation interface, it realizes process monitoring, data tracking and intelligent management, which greatly reduces labor costs.

Customizable Design

Support to customize special molds according to the samples provided by customers, and flexibly support the development of different candy shapes and specifications. Whether it is central filling or two-color double layer, it can be accurately realized.

High Output Capacity

The standard production capacity covers 150 kg/h to 1200 kg/h, which can be freely expanded according to the scale of customers’ factories to meet the different needs from small and medium-sized enterprises to large candy manufacturers.

Precision Dosing System

Advanced frequency conversion control system and quantitative pump are adopted to realize online inhalation and accurate proportion of auxiliary materials such as pigment, essence and acid solution, to ensure product consistency and quality stability.

Food-Grade Stainless Steel

All parts in contact with sugar are made of sanitary grade stainless steel to ensure production safety and meet international food hygiene standards.

Integrated Packing Solution

Support the connection with a variety of packaging equipment, realize the whole process linkage from molding, cooling to automatic packaging, and maximize production efficiency.

Expand Recommendation

- Jacketed Kettle: Improve the quality and taste of sugar.

- Continuous Cooling Cooler: Improve cooling efficiency.

- Automatic Candy Wrapping Machine: To meet the requirements of multi-specification packaging.

- Metal Detector: Ensure food safety and export compliance.

Whether it is an emerging brand or a large manufacturer, the molded hard candy production line is an ideal choice to achieve efficient and high-quality production. Welcome to contact us for samples, customized solutions and technical support!