Gondor Lollipop Forming Machine Introduction

In the highly competitive candy industry, efficiency, accuracy, and quality are the magic weapons to win. Lollipop forming machine is an innovative equipment born for this purpose, aiming at completely innovate your lollipop production process. Whether it is a traditional spherical lollipop or a novel and unique whistle stick, this equipment can be easily controlled, bringing you higher productivity, lower cost, and more stable product quality.

| Modle |

Outer size |

Voltage |

Powder |

Candy size |

Ball weight |

Capacity |

Machine weight |

| GD-400 |

100*900*1200mm |

220v/380v |

1.5kw |

18-35mm |

6-18g |

100-300kg/h

600-800pcs/min |

600kg |

The Broad Application Market of Lollipop Forming Machine

The ball lollipop forming machine is suitable for candy manufacturing enterprises of different sizes, including:

Food Processing PlantsCandy ManufacturersStartups & Entrepreneurs

In food processing plants, lollipop molding machine can realize large-scale and continuous production, meet the demand of a large number of orders, ensure the consistency of product size and quality, help enterprises respond to the market quickly and improve the overall production efficiency.

For candy manufacturing enterprises, the lollipop forming machine is the key equipment to enhance product diversity and competitiveness. It not only supports the production of lollipops with different tastes and specifications, but also reduces labor costs and achieves higher profit margins.

For individual entrepreneurs, a compact and user-friendly lollipop molding machine is ideal for entering the candy market. With low investment and quick learning, even small batches can produce high-quality products, boosting startup success.

Whether you are in mass production or small batch customization, this equipment can accurately meet your dual requirements of output and quality.

Extraordinary Performance Advantages of Ball Lollipop Forming Machine

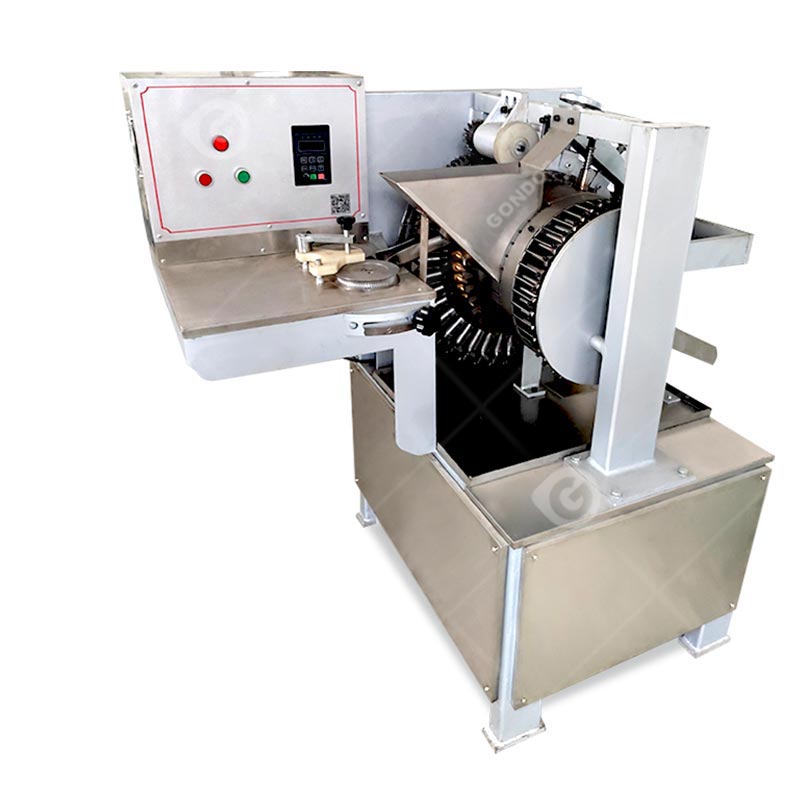

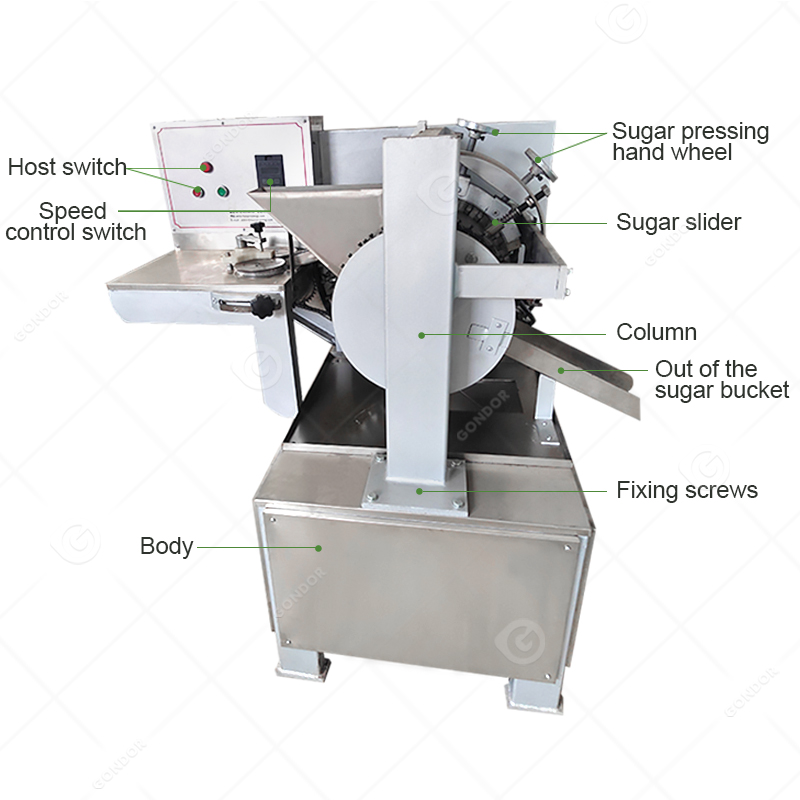

High Precision & Consistency

- Advanced mechanical design and an intelligent control system are adopted to ensure that the shape, weight, and size of each lollipop are highly consistent.

- The sugar wheel can be flexibly adjusted, and the size of the sugar balls can be easily changed to meet diverse market demands.

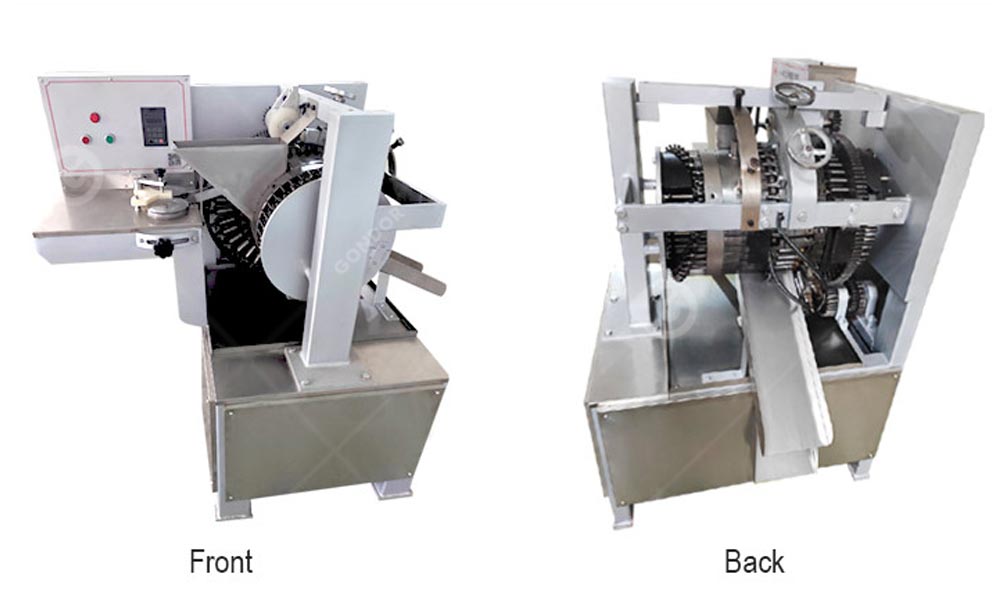

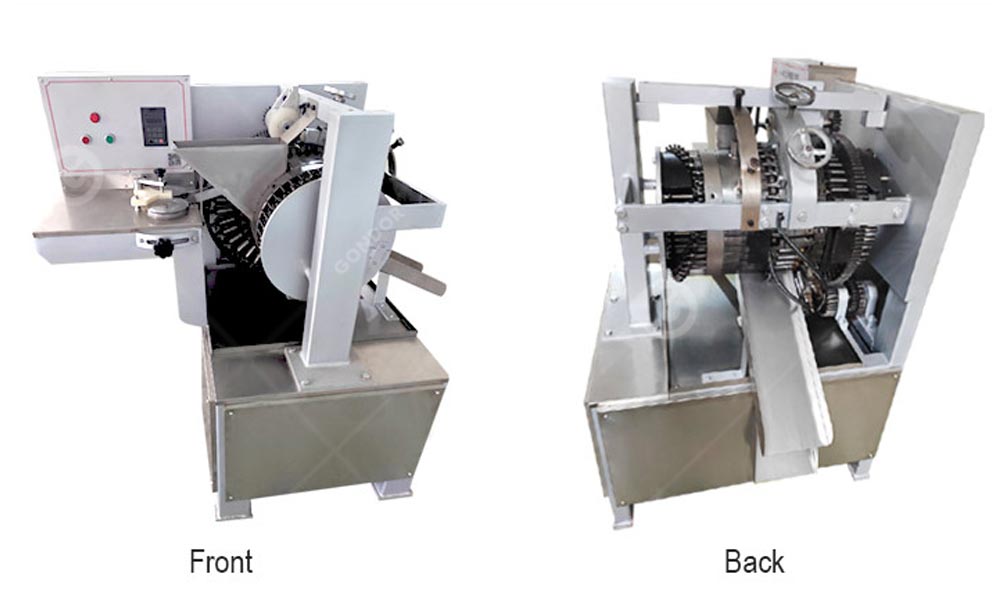

Compact Structure

The overall design of the equipment is exquisite, and it can operate efficiently even in a limited factory space.

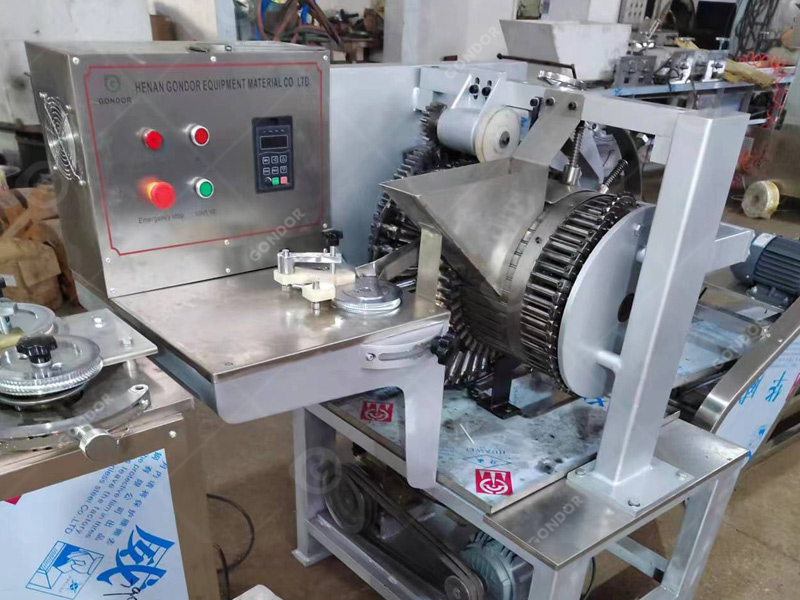

Hygienic & Easy Cleaning

All parts in contact with raw materials are made of food-grade SUS 304 stainless steel, which is rust-proof, corrosion-proof, simple to clean, and meets international food hygiene standards.

High Production Capacity

The lollipop forming machine has high production efficiency, which can greatly increase the output and help enterprises meet the market demand quickly.

Multiple Flavors & Shapes

Can produce a variety of flavors and types of lollipops, from traditional tastes to customized features, to meet the individual needs of different customers.

High Automation Level

The machine is equipped with an intelligent control panel, with a friendly interface and simple operation, which reduces the dependence on operators and greatly reduces labor costs.

Low Noise Operation

The pressing wheel has excellent design, stable operation, extremely low noise, and an optimized production environment.

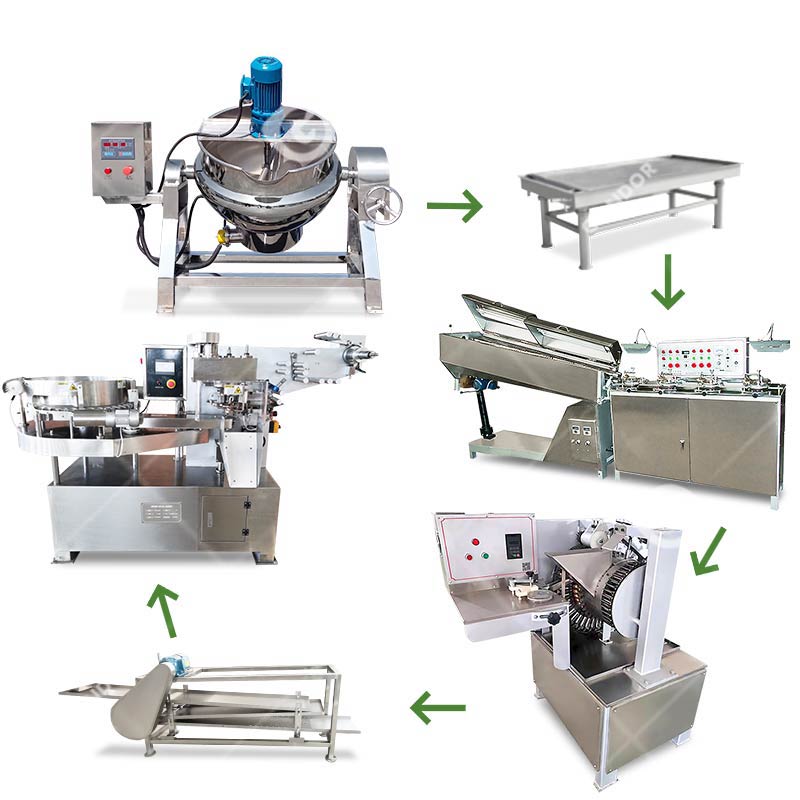

More Intelligent Candy Equipment Will Help You Upgrade the Whole Line

In addition to a lollipop forming machine, we also provide a range of high-end candy production equipment, including a candy depositor machine, a chocolate coating machine, and packaging machines, to help you create an integrated solution from production to packaging. If you need more candy production equipment, please contact our professional team, and we will provide you with tailor-made and efficient production solutions!