Candy Coating Machine

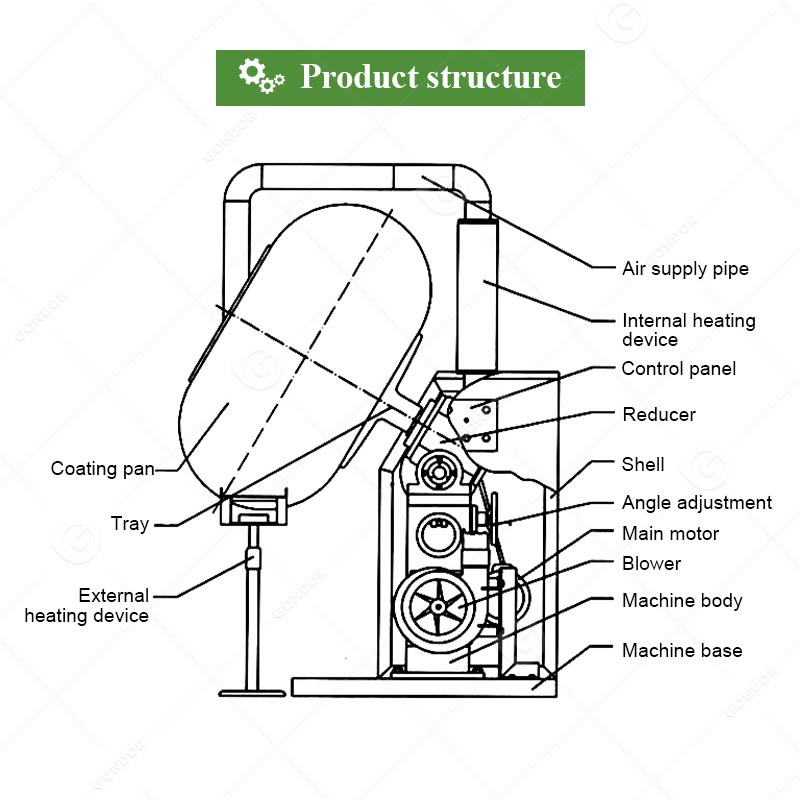

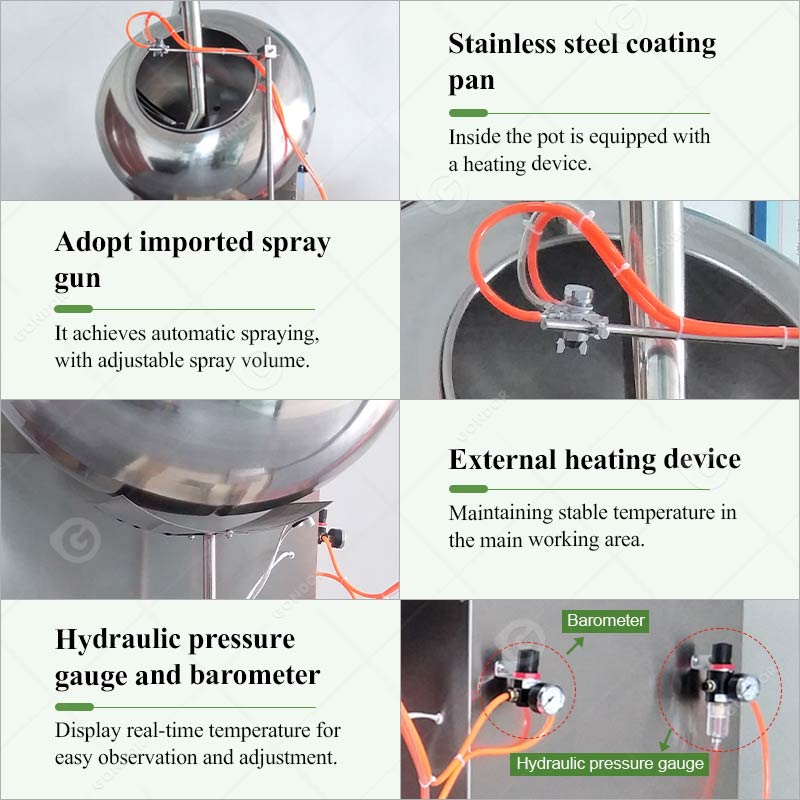

As one of the indispensable and important equipment in modern food and pharmaceutical processing, the candy coating machine not only has many advanced functions, but also can efficiently complete the coating, polishing, and mixing processes of granular materials such as candy, dried fruit, nuts, seeds, and tablets. The equipment integrates automatic liquid spraying, internal and external heating, temperature control, and an adjustable speed system, thus realizing rapid film formation and uniform coloring. At the same time, the whole machine is made of food-grade stainless steel, which meets GMP hygiene standards, and the internal and external walls are smooth without dead ends, which is very suitable for the high-standard production needs of the modern food industry and pharmaceutical industry.

| Model | Pot Diameter | Rotating Speed | Main Motor Power | Blower Power | Heating wire power | Productivity | Dimension | Net Weight |

| GDJ-400A | 400mm | 50r/min | 0.37KW | 40W | 1KW | 2-5kg/batch | 770*670*840mm | 70kg |

| GDJ-600A | 600mm | 0.75KW | 120W | 2KW | 8-15kg/batch | 930*620*1140mm | 120kg | |

| GDJ-800A | 800mm | 1.5KW | 200W | 2KW | 30-50kg/batch | 1100*800*1600mm | 180kg | |

| GDJ-1000A | 1000mm | 2.2KW | 250W | 4KW | 50-70kg/batch | 1200*1200*1600mm | 260kg | |

| GDJ-1250A | 1250mm | 2.2KW | 370W | 4KW | 80-150kg/batch | 1350*1350*1600mm | 360kg |

Application Field of Candy Coating Machine

This candy coater has performed well in many industries, such as food, pharmacy, and the chemical industry, and can be widely used in the following scenarios:

Excellent Performance Advantages of Candy Panning Machine

Equipment Scheme: Complete in One Stop

In order to realize a one-stop solution from raw material processing to product packaging, we also provide the following supporting equipment for you to choose from:

- Mixing Machine: Quickly and evenly mix the ingredients of the formula.

- Drying Machine: Remove excess water in materials to ensure the stability of finished products.

- Packaging Machine: Efficient packaging of finished products, improving sales efficiency and aesthetics.

Choose our candy coating machine, and you will get lower material waste, higher coating efficiency, more beautiful product appearance, and significantly enhanced product market competitiveness. Whether it is a candy factory, a snack factory, or a pharmaceutical company, you can easily integrate cost-effective equipment into your existing production line.