Automatic 3D Gummy Candy Depositing Line

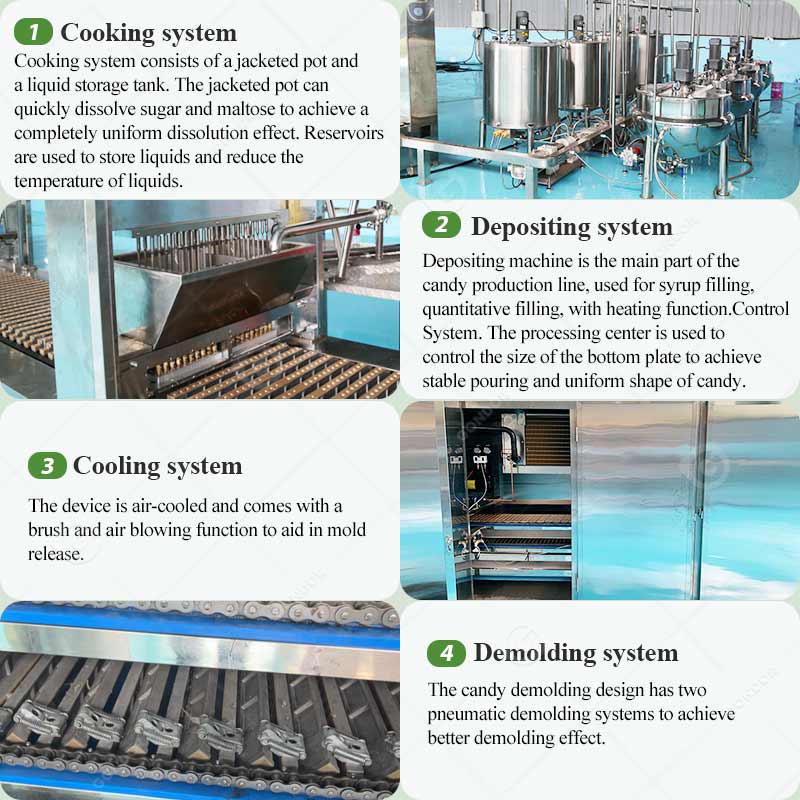

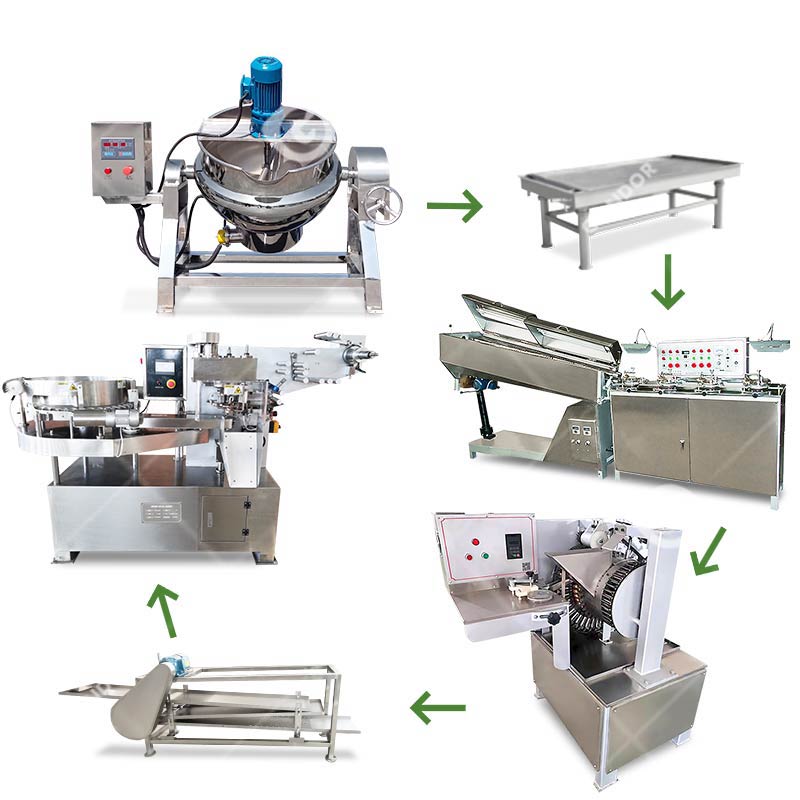

3D gummy candy production line integrates raw material treatment, sugar liquid cooking, ingredient blending, precise pouring, rapid cooling, automatic demoulding, and diverse packaging. The whole line is suitable for producing single-color gummy candies, two-color gummy candies, sandwich gummy candies, and gel-filled gummy candies with exploding effects. By supporting mold customization, you can easily create a variety of 3D, brand-specific shapes or festival-themed candy, and truly realize “multi-purpose” and “ever-changing customization”.

3d Gummy Production Line Specification

| Model | GD-150 | GD-300 | GD-450 | HQ-600 |

| Standard production volume(kg/hour) | 150 | 300 | 450 | 600 |

| The sugar weight | 2-6g | 2-6g | 2-6g | 2-6g |

| Pouring rate | 30-35n/min | 45-55n/min | 45-55n/min | 45-55n/min |

| Work environment requirements | Temperature:20-25℃ humidity:55% | |||

| Overall weight | 3800kg | 4000kg | 4500kg | 5000kg |

| Overall length | 15.8m | 17m | 17m | 20m |

Target Market of Gummy Candy Production Line

It can produce functional soft candy containing vitamins, minerals, collagen, probiotics, and other ingredients, which conforms to the global health trend.

It is suitable for customizing personalized soft candy for brands, supporting small-batch diversified production, and meeting the needs of personalized and creative candy.

It is suitable for the production of children’s candy, holiday gift candy, retail fun soft candy, and other mass consumption products, with a novel appearance and strong attraction.

Support the production of pharmaceutical-grade soft candy, such as children’s medicinal chewing candy, sleep-helping soft candy, etc., with accurate dosage and convenient administration.

It conforms to the food laws and regulations of many countries, is suitable for export and overseas factory application, and meets the market tastes and packaging standards in different regions.

Competitive Advantage of Gummy Production Equipment

Customize Your Own Gummy Candy Factory

- Doypack Packing Machine: Realize efficient packaging and support automatic packaging of multi-specifications and types of soft sweets.

- Candy Coating Machine: Add outer wrappers such as sugar powder and acid powder to improve the taste and commodity value of soft candy.

- Multi-Head Scale Batching System: Automatically weigh and combine different soft sweets to realize diversified mixed packaging.

Whether you want to make nutritious gummy candy, creative gift candy, or launch your own brand of gummy candy, our 3D gummy bear machine can meet the performance, flexibility, and accuracy required by your business. Let your creativity take shape in every candy!