Lollipop Depositing Production Line

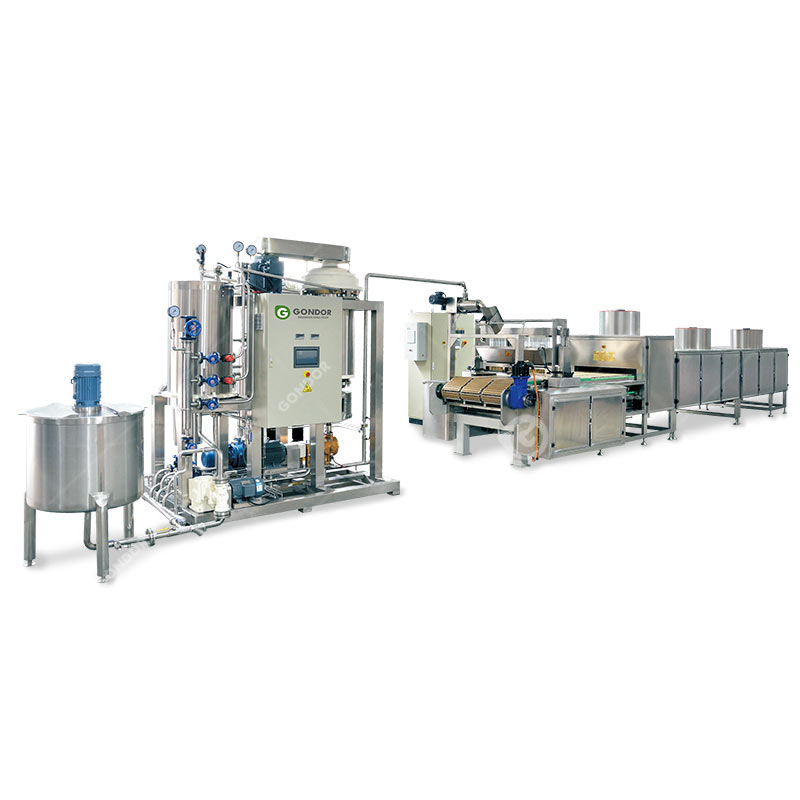

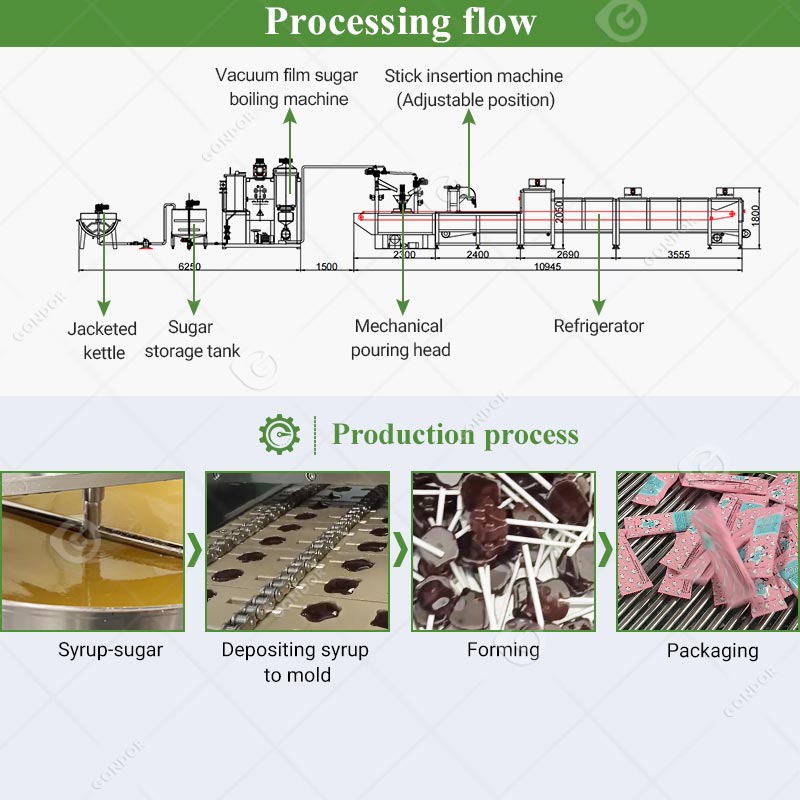

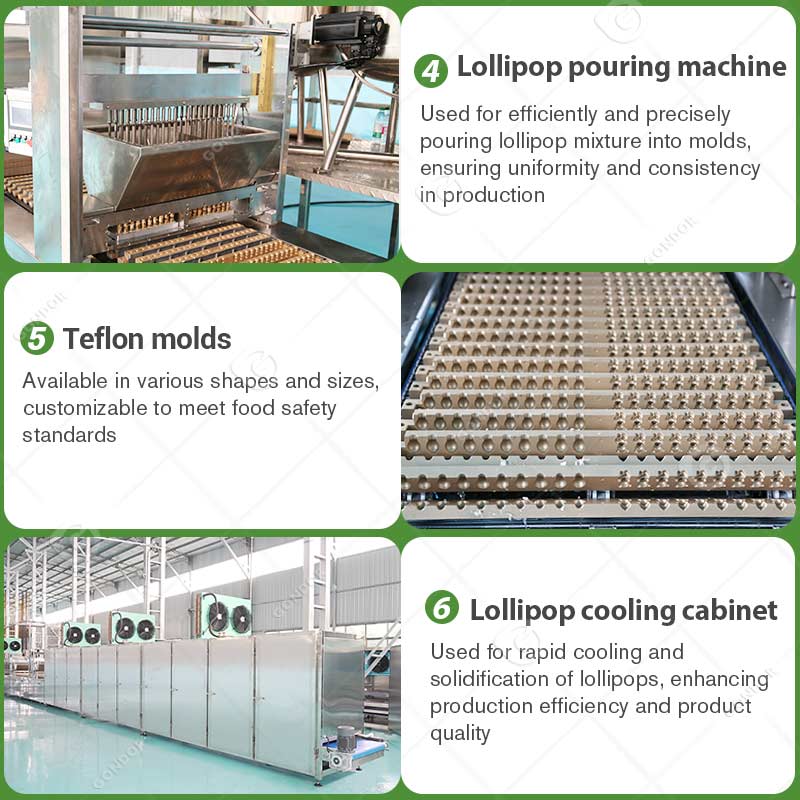

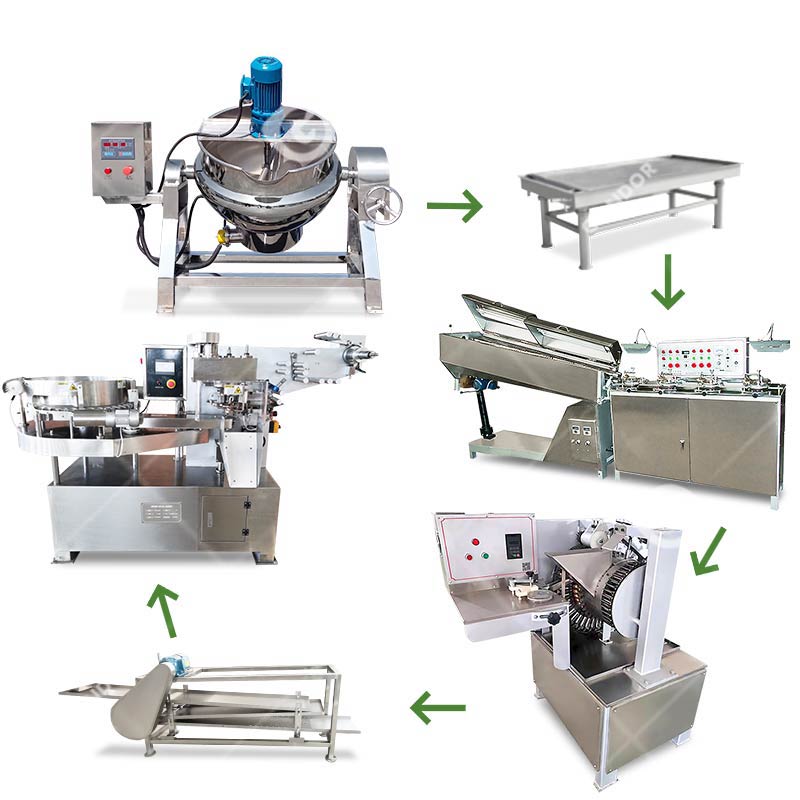

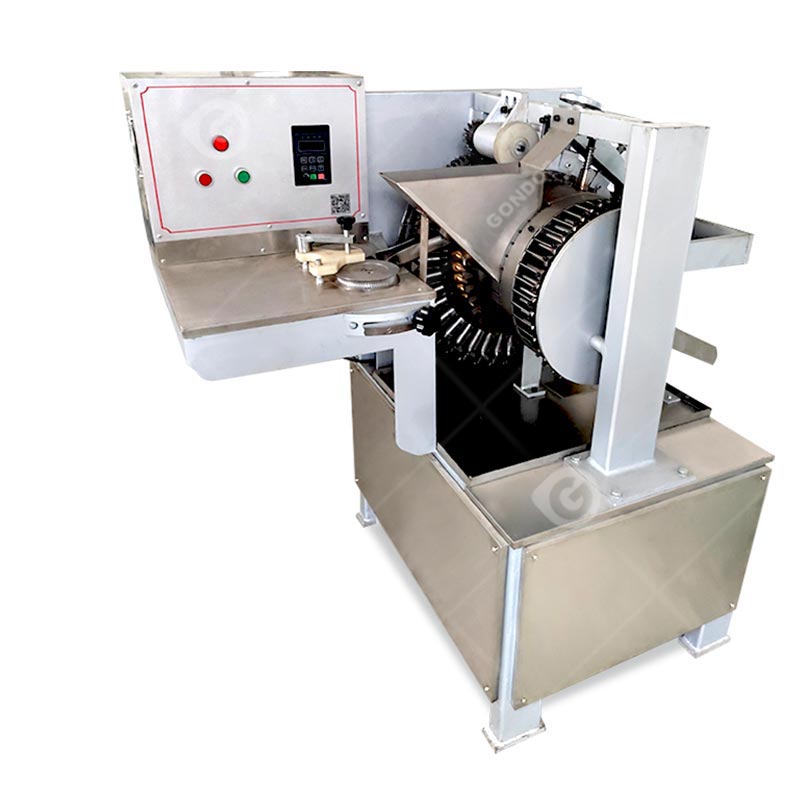

In order to meet the market demand for high-quality lollipops, our company launched a fully automatic lollipop production line, adopting advanced PLC/ computer control system to realize the automation of the whole process from raw material treatment to packaging, and improve production efficiency and product quality. The production line has compact structure, stable operation and convenient maintenance. The production capacity covers 300kg/h to 800kg/h, and it can flexibly adapt to different needs. The equipment is made of international brand components, matched with sugar boiling pot, vacuum sugar boiling machine, pouring machine, Teflon mold and cooling cabinet to ensure that each step is accurate and efficient, and the full process is controllable and traceable.

| Model | GD150B-S | GD300B-S | GD450B-S | GD600B-S | GD1200B-S |

| Capacity | 150kg/h | 300kg/h | 450kg/h | 600kg/h | 1200kg/h |

| Lollipop weight | As per the lollipop shape and size | ||||

| Depositing speed | 25-35n/min | 30-60n/min | |||

| Steam requirement | 250kg/h,0.5-0.8MPa | 300kg/h, 0.5-0.8MPa |

400kg/h, 0.5-0.8MPa |

500kg/h,0.5-0.8MPa | 1200kg/h,0.5-0.8MPa |

| Compressed air requirement | 0.2m3/min,

0.4-0.6MPa |

0.2m3/min,

0.4-0.6MPa |

0.2m3/min,

0.4-0.6MPa |

0.3m3/min,

0.4-0.6MPa |

0.6m3/min, 0.4-0.6MPa |

| Working condition | Temperature 20°C-25°C; Humidity45-55% | ||||

| Electric power needed | 18kW/380V | 27kW/380V | 34kW/380V | 38kW/380V | 56kw/380V |

| Total length | 17m | 19m | 19m | 22m | 40m |

| Weight of machine | 4000kg | 5000kg | 6000kg | 7000kg | 12000kg |

Application Market of Lollipop Production Line

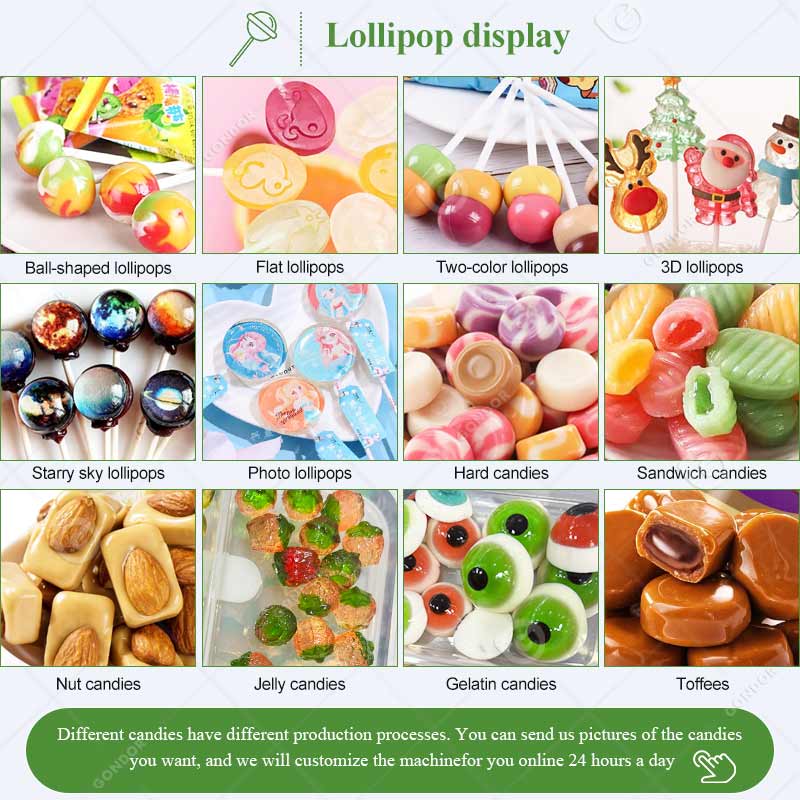

This lollipop depositing line is widely used in candy factories, OEM candy brands and innovative candy enterprises pursuing diversified products. Both the traditional fruit-flavored lollipop and the creamy taste with sandwich can be easily realized in this production line. More importantly, this production line supports rapid replacement and customization of multiple molds, and can produce lollipops with different shapes, sizes and patterns, which is suitable for children's day, Valentine's Day, Halloween and other festivals.

Functional Advantages of Lollipop Making Machine

Matching Equipment

In order to achieve a complete candy solution, we can also provide you with the following supporting equipment:

- Automatic Packaging Machine: It is suitable for high-speed packaging of single or multiple lollipops and supports various packaging forms.

- Cooling Tunnel: Rapid cooling and shaping to improve the stability and aesthetics of finished products.

- Flavoring/Filling Injection System: It is used to make innovative products such as cream filling and jam filling, and enrich the product line.